VCCS

Valved Corrosive Material Cracker Source

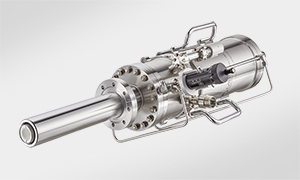

VCCS 100-420 Sb valved corrosive material cracker source on DN100 CF (O.D. 6") mounting flange (with adapter flange VADP 100-63-K)

-

Evaporation and cracking of Sb, Te, Mg, and other corrosive materials

-

Large crucible capacity of 420 cm³

-

All PBN construction of valve and cracker stage

-

Fast, stable and reproducible flux control

-

Easy installation and refilling procedure

-

Injector length and mounting flange adjustable to fit most MBE systems

|

The Valved Corrosive Material Cracker Source VCCS is designed for controlled injection of radicals of antimony, tellurium, magnesium or other corrosive materials in standard MBE applications. Parts directly exposed to the evaporant like crucible, valve mechanism, injector tube and cracker are solely made from PBN to minimize corrosion of the cell. |

Additional equipment for the VCCS (motorized valve control unit MVCU with temperature controllers and power supplies) |

|

|

Operation of the mechanical valve unit shows fast, stable and reproducible flux control. Together with our valve controller MVCU an easy handling and integration into your MBE system is provided. |

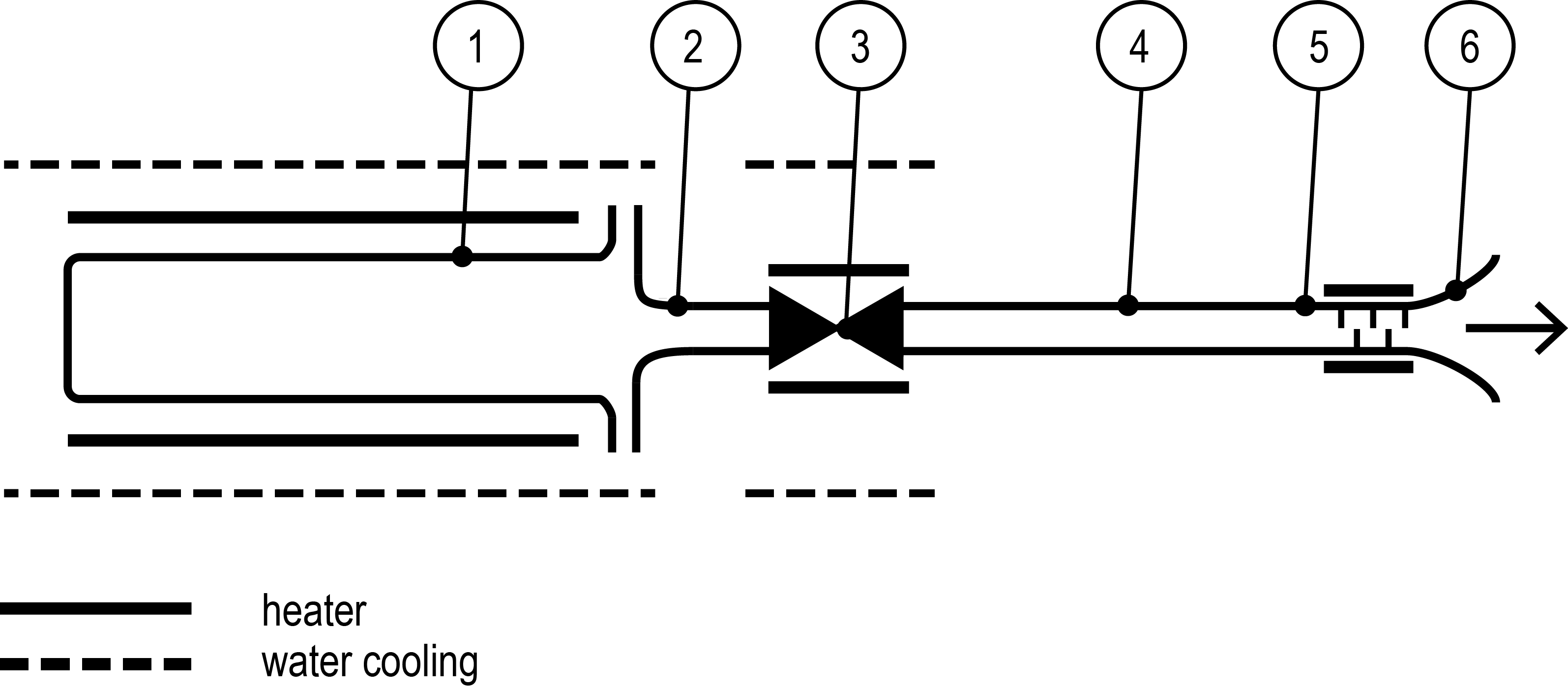

Schematic sketch of the VCCS building blocks. The PBN-funnel (2) connects the PBN reservoir (1) with the full-PBN valve (3). The evaporant is guided to the cracking stage (5) by a PBN injector tube (4). For better homogeneity there is a beam shaping funnel (6) on the orifice of the VCCS. |

Application

The main purpose of the VCCS in MBE applications is enhanced flux control and cracking of materials whose vapor is highly corrosive to metallic surfaces. The VCCS was originally designed as a source for an antimony radical (Sb2) molecular beam as group V material in standard III-V MBE. It uses the well-established concept of sublimation of elemental Sbn followed by a step of thermal dissociation in a cracker stage to produce a Sb2 molecular beam. The VCCS all PBN construction of the inner parts, in particular the valve mechanism, in combination with the flexibility provided by three independent heater circuits allows applying this concept to other materials like Te, Mg or Se.

The valve mechanism and hence the beam flux can be regulated either manually or remotely by a servo motor drive (MVCU) with a 0-10 V analogue input signal.

A large crucible capacity of 420 cm³, fast and precise flux control and easy handling for maintenance and crucible refill make the VCCS an ideal source for smaller production MBE systems as well as for higher throughput research MBE systems.

References

Several publications based on samples grown with VCCS sources are listed in section References / List of Publications.

Technical data |

|

| Filament type | 3 separate heater-circuits (cell / valve / cracker) |

| Thermocouple | 3 W5%Re/W26%Re (type C) thermocouples (cell / valve / cracker) |

| Operating temperature (for Sb-sublimation) |

cell crucible: 550-650°C; valve: 600-700°C; cracker: 650-1200°C |

| Outgassing temperature | cell crucible: 800°C; valve: 900°C; cracker: 1300°C |

| Bakeout temperature | 250°C |

| Cooling | integrated water cooling shrouds |

| Crucibles | 420 cm³ |

| Flux control |

integrated all PBN valve mechanism / cell temperature |

| Valve control | stepper motor drive with control unit MVCU |

Dimensions

|

Schematic drawing of the Sb-Valved Corrosive Material Cracker Source VCCS (drawing shows VCCS 100-420 with VADP adapter) |

Specific data

For general information on CF mounting flanges see Flange and Gasket dimensions.

|

|

|

|

|

||

|---|---|---|---|---|---|---|

| [cm3] | [mm] / [mm] | [W] / [A] | Product code | |||

| VCCS | 100* - | 420**- | LxxxD38 | cell : 315 / 9 valve : 400 / 8 cracker : 455 / 13 |

cell : PS 60-12.5-C valve : PS 60-12.5-C cracker : PS 40-19-C |

| * | other mounting flange diameters feasible in combination with VADP adapter flanges (on request) |

| ** | other capacities on request |

| *** | specify UHV length L with order |

Product code:

e.g. VCCS 100-420-L305D38

is a valved corrosive material cracker source on DN100 CF flange with 420cm³ crucible and UHV-length 305mm.

Related products

The following list provides suggestions for related products. For additional product suggestions or more detailed information, please contact us.

Components

|

|

|

| Valved Thermal Cracker Cell VTCC |

Thermal Cracker Cell TCC |

Accessories

|

|

|

| Motorized Valve Control Unit MVCU |

Beam Flux Monitor BFM |

Systems

|

|

|

| OCTOPLUS 400 | OCTOPLUS 600 |