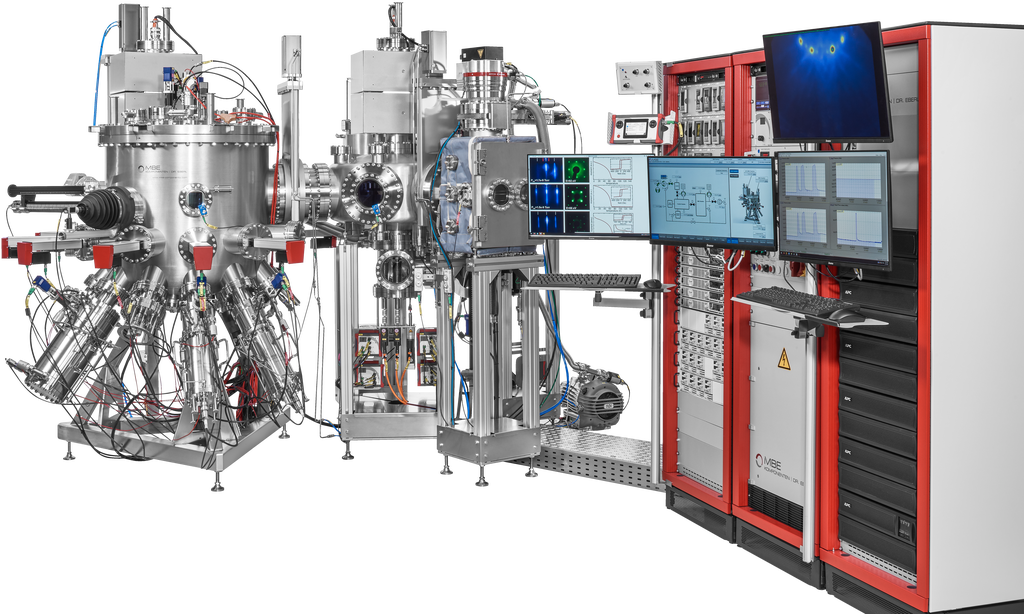

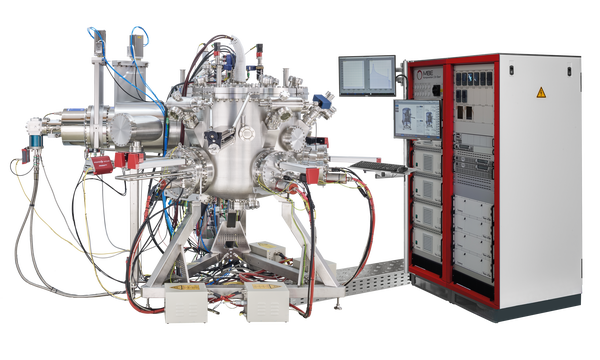

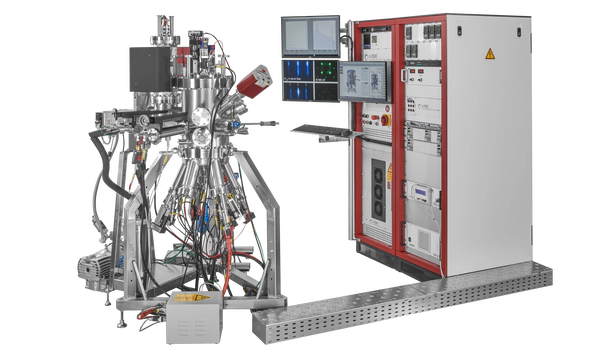

State-of-the-art MBE system for semiconductor device production

- Applications: III/V, II/VI or other material heterostructures

- Substrate sizes 200mm, 150mm or 4 x 3-inch or 7 x 2-inch wafers, with face-down geometry

- Optional 800+ version with multi-wafer 4 x 4-inch and 7 x 3-inch capability

- Smaller footprint, smarter design: optimized deposition geometry enables up to 50% more material output than conventional 4×4" wafer systems.

- Wide range of source options, e.g. effusion cells, valved cracker sources, etc.

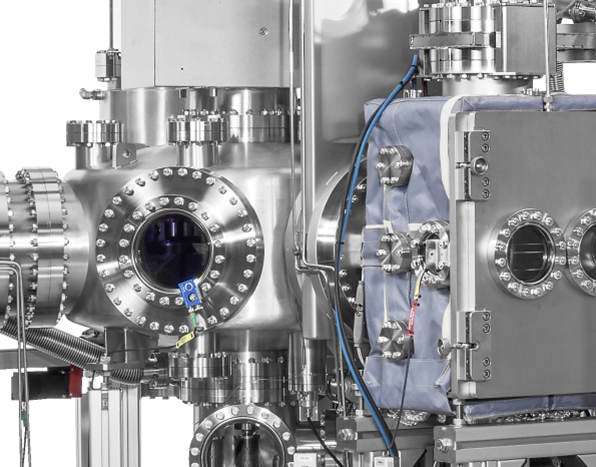

- LN2 cooling shroud and high-performance UHV pumping system

- In-situ characterization capability, customizable to your needs

- 12 large source ports

- Fully automated wafer transfer

- Extensive in-situ characterization capability

- Professional support by PhD MBE experts

General Information

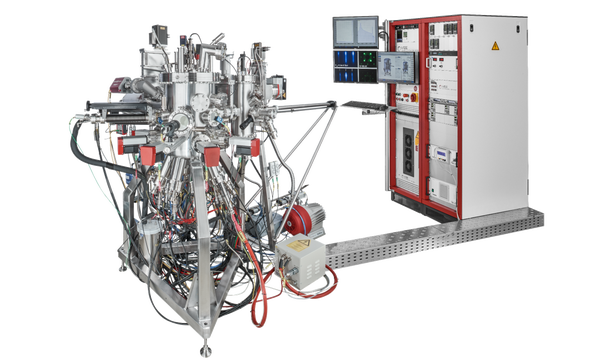

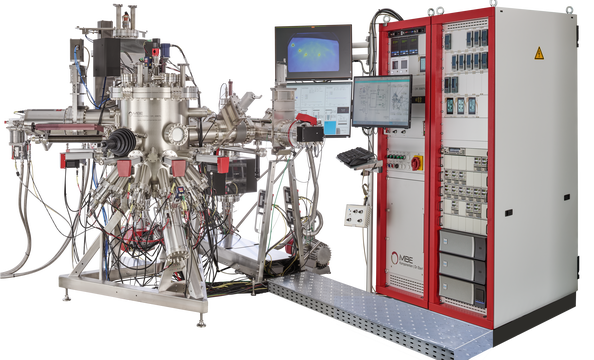

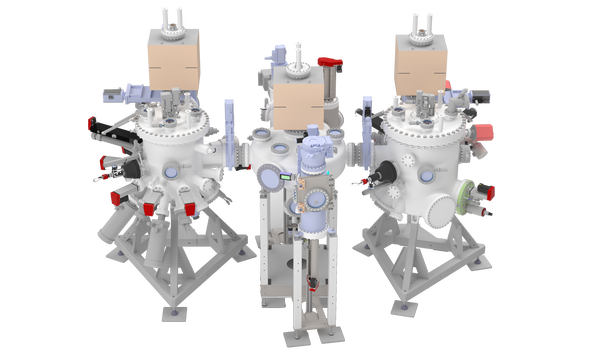

The OCTOPLUS 800 allows the MBE growth on multi wafer and single 150mm or 200mm substrates. It exhibits 12 large source ports for high capacity effusion cells, valved crackers and other sources. Depending on the application, the substrate manipulator applies to Graphite, SiC, free standing tungsten or tantalum heaters with PBN diffusor plate.

The OCTOPLUS 800 MBE system offers highly reproducible sample quality, it is field-proven and ideally suited for III/V, II/VI and other compound semiconductor layer growth for applications in production of semiconductor devices.

The OCTOPLUS 800 is in use in leading research institutes and industrial laboratories. On demand we provide a list of references. Please contact our sales department for further information.

The OCTOPLUS 800+ sets the standard for efficient, reproducible MBE growth of III‑V compounds and advanced heterostructures in a multi‑wafer configuration. With capacity for up to 12 sources on DN125CF flanges, the system offers exceptional flexibility for complex material designs.

Tailored substrate manipulators with a wide range of heater options ensure precise temperature control, perfectly adapted to your process needs. Proven in real‑world applications, the OCTOPLUS 800 combines reliability, scalability, and performance - making it the ideal choice for pioneering research and high‑value production.

High reliability and versatility are outstanding features of the OCTOPLUS 800 system. With the standard version already comprising 12 radially arranged source ports, the OCTOPLUS 800 can be further expanded and customized with additional source ports on request.

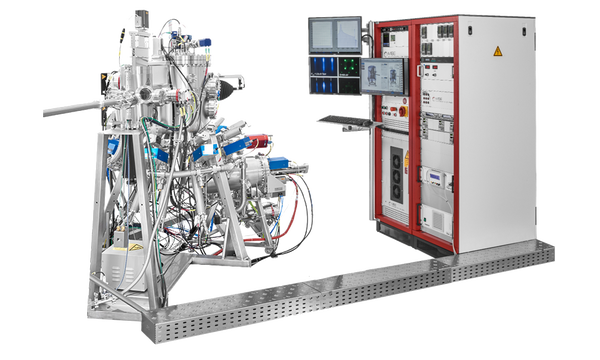

A rapid pump-down load lock chamber with wafer magazine, a heated station and the fully automated central transfer allows easy substrate introduction and handling.

Options for OCTOPLUS 800

- Additional load-lock, heated station, or buffer chambers

- Wide range of components, e.g., effusion cells, e-beam-evaporators, sublimation sources, valved cracker sources, gas sources, manipulators

- Software/hardware control system

- Pumping system (cryopump, turbo, ion, white phosphorous recovery)

- In-situ monitoring tools, e.g. RHEED, BFM, quartz microbalance, pyrometer, band-edge thermometry, ellipsometry

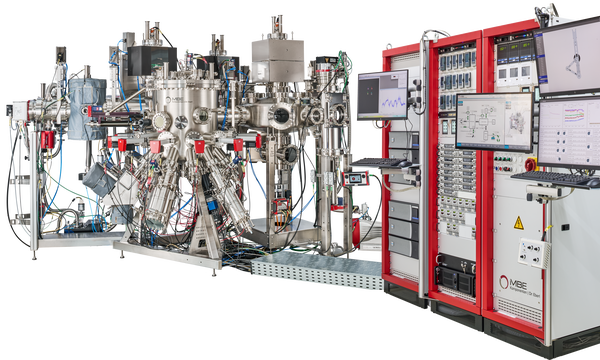

Technical Data

| Size of deposition chamber | 800 mm I.D. |

| Base pressure | < 5x10-11 mbar |

| Pumping | TSP, ion getter pump, cryopump and/or turbopump |

| Cooling Shroud | LN2 or other cooling liquid on request |

| Substrate heater temperature | up to 800°C, or up to 1200°C |

| Substate size | 200mm, 150mm or 4 x 3-inch or 7 x 2-inch wafers Option 800+: 4 x 4-inch or 7 x 3-inch wafers |

| Bakeout temperature | up to 200°C |

| Source ports | 12 ports DN125CF / DN150CF |

| Source types | effusion cells, e-beam evaporators, sublimation sources, valved cracker sources, gas sources |

| Shutters | soft-acting linear shutters |

| In-situ monitoring | ion gauge, QCM, pyrometer, RHEED, QMA, temperature control by kSA or Laytec, wafer curvature etc. |

| Sample transfer | fully automatic in face-down geometry |

| Load lock | magazine with 10 substrates, with rapid pump down |

| MBE control software | Tiny Tusker |

| Service | system installation and acceptance testing |

| MBE training | by MBE experts with extensive application know-how |

Examples for applications and corresponding sources

| Effusion Cells WEZ , NTEZ OME , HTEZ | Sublimation Sources SUKO , SUSI HTS , DECO | Valved Sources VACS , VGCS VCS , VSCS | Plasma Sources FMP | E-Beam Evaporators EBVV | |

| III/V | Ga, In, Al | C, Si doping | As, P, Sb | ||

| II/VI | Zn, Cd, Be | S, Se, Te | N-doping | ||

| IV | Ge, Sn, Pb | B, P, Sb doping | Si, Ge | ||

| GaN | Ga, In, Al | N | |||

| Metals | Cu, Al, Ni, Co, ... | Pt, Ta, Pd, Mo, W | |||

| Topological Insulators | Ge, Sn, Te, Bi, GeSb | Se, Te | B |

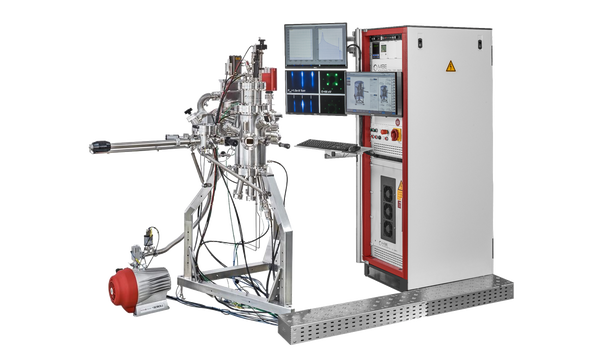

Trusted expertise since 1990

Based on many years of active research experience in the field of growth and doping applications our team develops and manufactures the OCTOPLUS 600 system and all essential components. Each product is assembled and carefully tested in-house.

We are happy to discuss your MBE system specifications and give

competent advice for your application.

The OCTOPLUS 600 is in use in leading laboratories. On demand we

transmit a detailed list of references. Please

contact our sales

department for further questions and specification information.