- UHV compatible, low outgassing

- High flux rates of low vapour pressure materials

- High-purity evaporation

- Hearth volumes: 40 cm³, 100 cm³, 160 cm³ or 1000 cm³

- Long filament lifetime

- Easy maintenance

- Optimized versions for SiGe MBE available Datasheet

Introduction

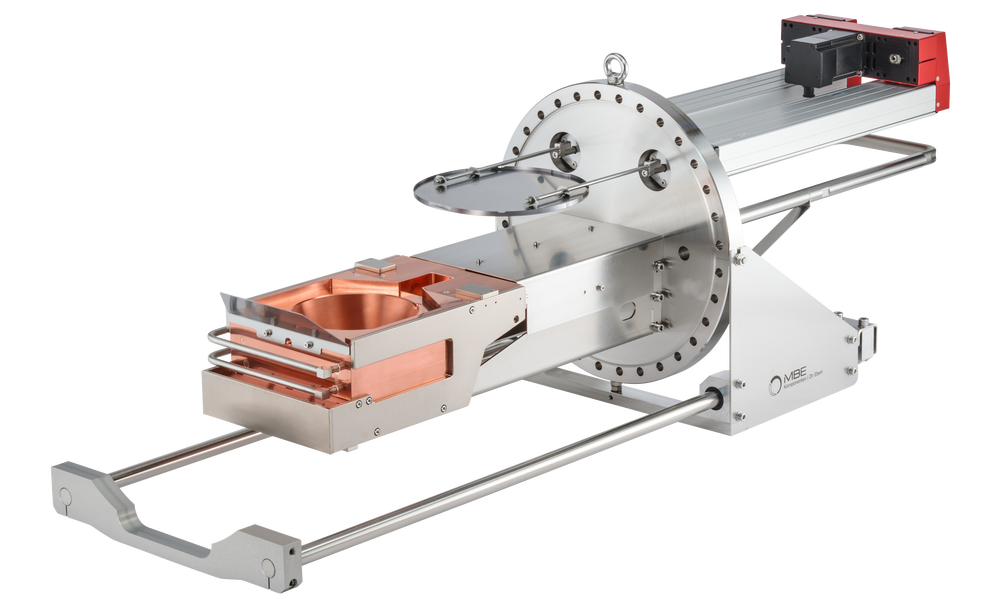

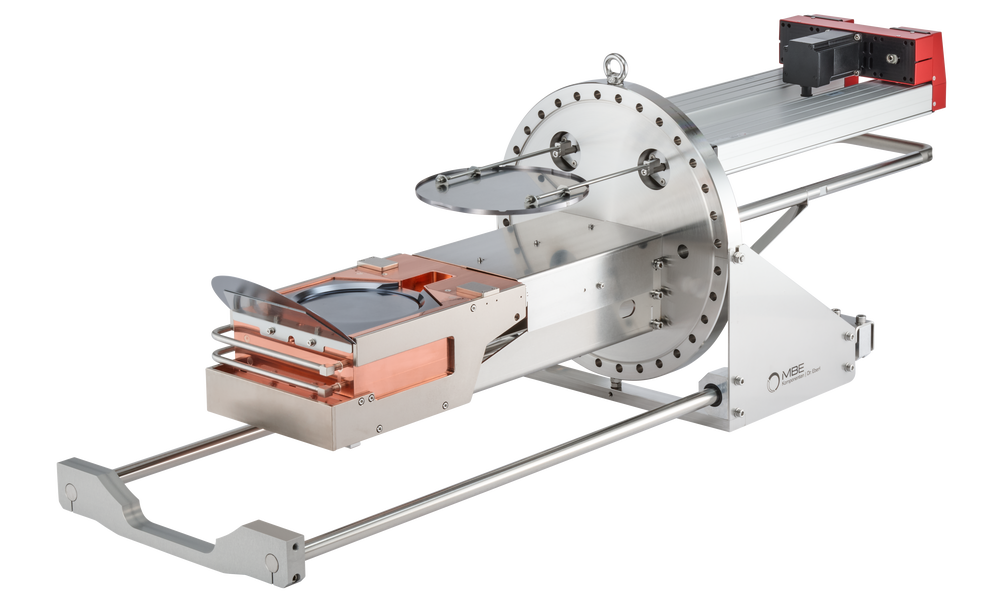

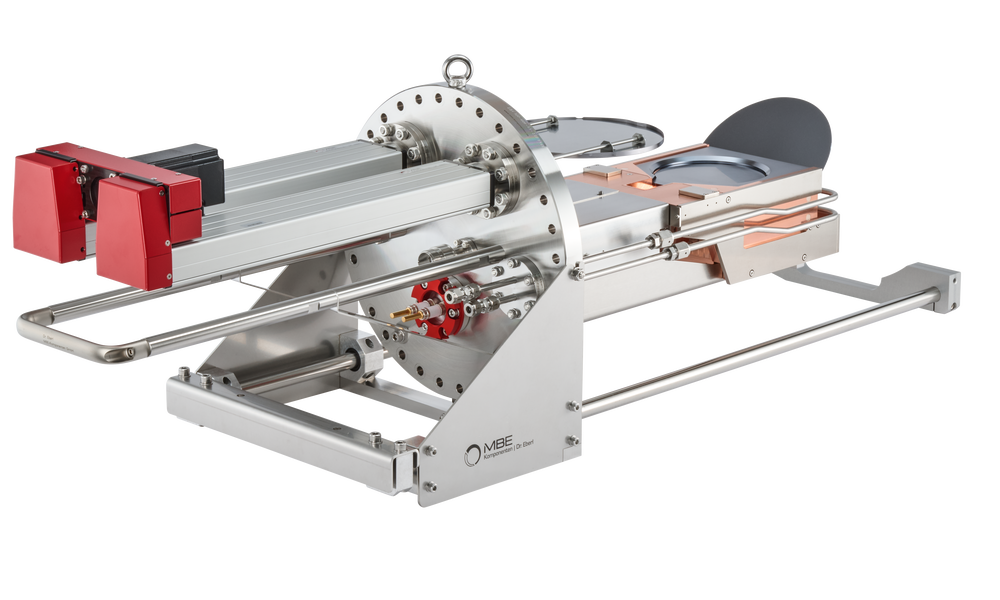

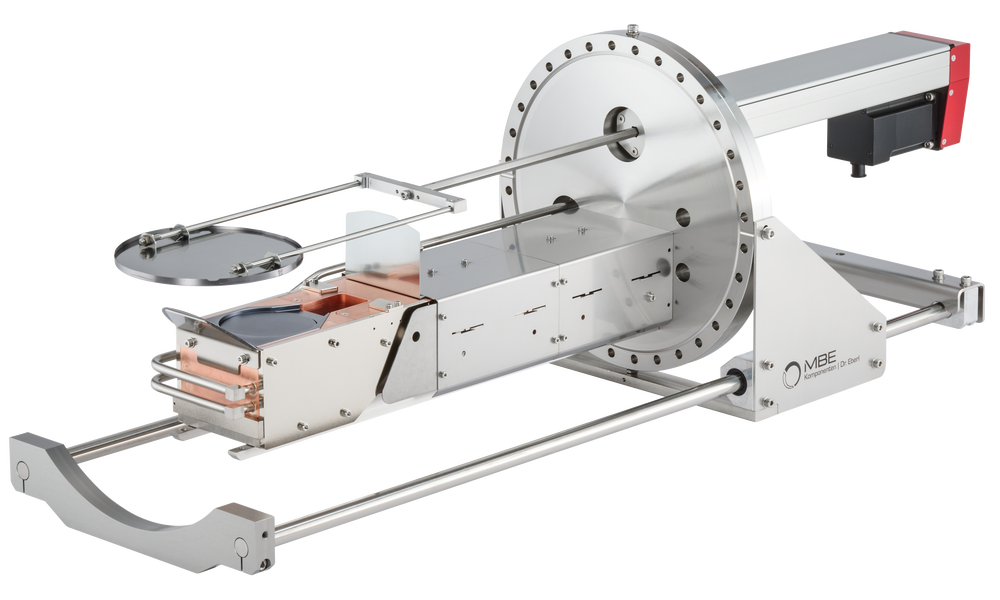

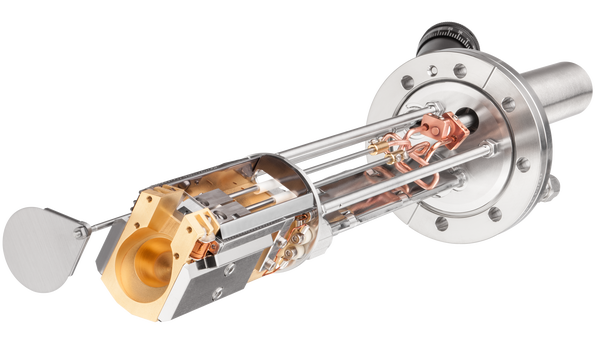

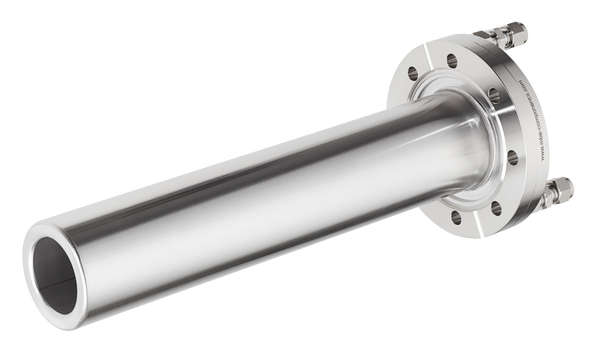

The standard Electron Beam Evaporator EBV is an evaporation source

intended to achieve high growth rates for low vapour pressure materials,

especially when high purity of the evaporant is desired. Large hearth

capacities ensure a long system up-time before evaporant is depleted.

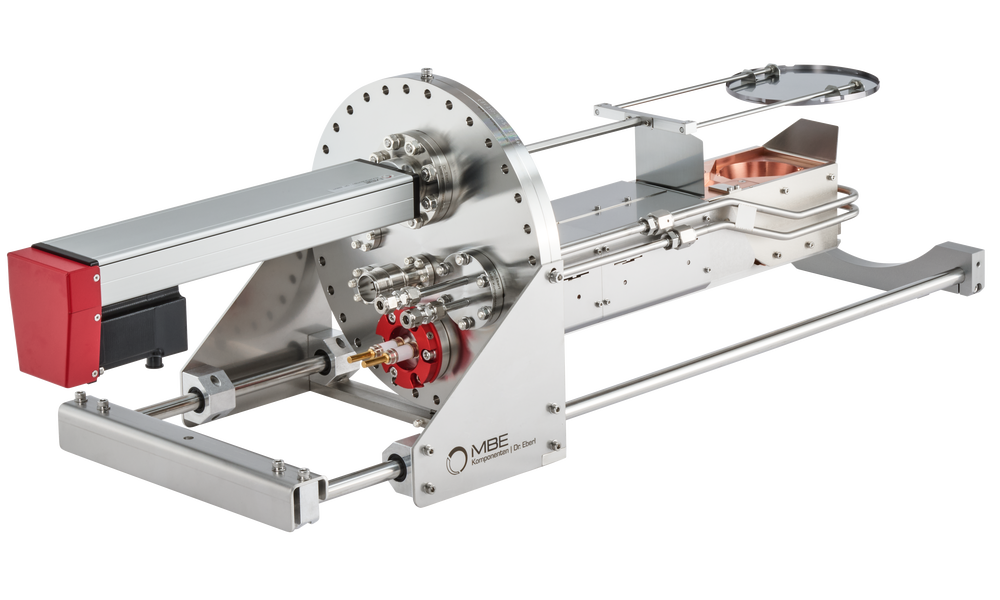

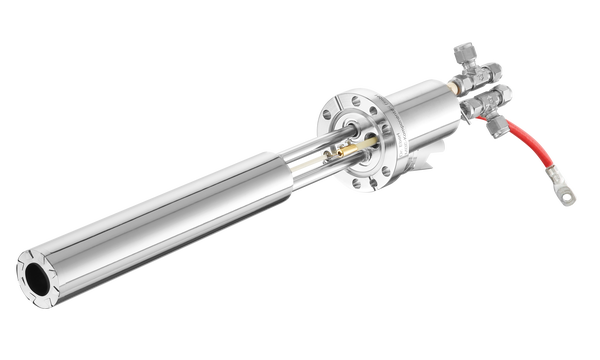

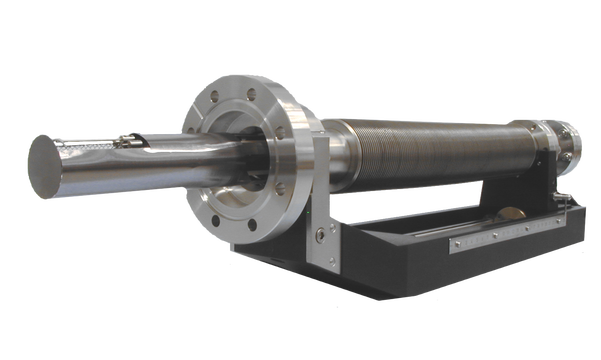

Our series of standard electron beam evaporators EBV are single-pocket

UHV evaporators mounted horizontally on base flanges from DN200CF up to

DN300CF. For all models a mounting-slide is offered that allows easy

handling and service of the EBV.

Only UHV-grade materials are used for its construction without any compromise, obtaining a design that is bakeable up to 250°C. In the hot areas of the emitter only high-purity low vapour pressure materials like Mo, Ta, W or Al 2 O 3 are present.

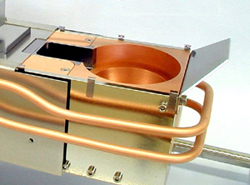

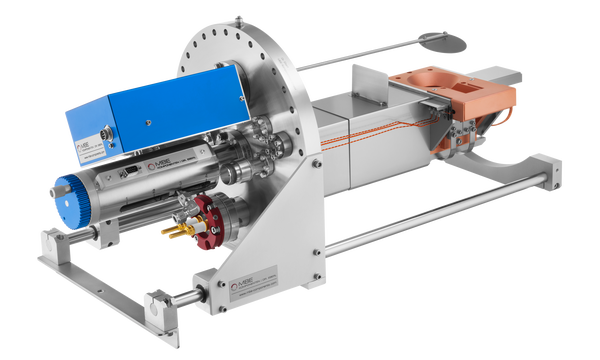

The electron emitter is designed with 270° beam deflection, eliminating nearly all ion bombardment effects on the filament. The electromagnetic coils are manufactured from Kapton TM (polyimide) isolated wires and nickel-plated magnetic steel, the permanent magnets are of a high temperature rare earth material and the single-hearth crucible is manufactured from a high purity OFHC-copper block (Oxygen-Free-High-Conductivity Copper). The crucible capacity can be chosen between 40 cm³, 100 cm³ and 160 cm 3 , machined into the copper block. The cooling of the copper block is effectively accomplished by two complete turns of water bores closely around the hearth.The electron emitter is designed in a way that eliminates nearly all ion bombardment effects on the filament. This is due to the 270° beam deflection and the very sharply bent electron beam path near the exit of the asymmetrical emitter aperture. Thus it is well shielded from evaporant or charged particles ejected from the crucible (see Fig. in the right. In addition, the 270° emitter design shields the sample from a direct sight onto the hot tungsten filament further reducing the chance of sample contamination by impurities from the hot emitter area.

Application

EBV evaporators are designed for high rate evaporation of low-vapour-pressure materials, especially when high purity of the evaporant is desired. They are frequently used for evaporation of refractory metals, e.g. Mo, Nb, Ta, W, Zr, it is well suited for high-rate evaporation of Al, and of course also for semiconductors like Si and Ge. A typical application of the EBV is SiGe MBE.

For application in a silicon MBE system we provide a specially adapted set of shielding parts manufactured from high-purity single-crystalline silicon. These plates and rings cover all parts of the metallic body that are potentially subject to electron or ion bombardment and that face the substrate. Only this Si-shielding allows the growth of highest purity Si-based films with virtually no metallic contamination. We also supply high purity Si source material in superior quality, machined from wafer-grade Si-single crystals, fitting the evaporator hearth closely.

For germanium evaporation with the EBV 200-100, a crucible liner made from high purity silicon is available. Ge does not sublime, but has to be molten completely for evaporation. To prevent it from interacting with the copper hearth, this “Si-crucible” is used, leaving a capacity of about 50 cm³ for the Ge evaporant.

For metal deposition the EBV can be used “as is” for all metals that do not melt completely or that do not react with the cooled Cu-wall. For some metals, graphite- or other metal crucible-liners are used. Ask for the solution for your particular evaporant.

Technical Data

| Mounting Flange | DN200CF (O.D. 10"), DN250CF (O.D. 12"), DN300CF (O.D. 14") |

| Filament type | short-legged coil of thick W wire, electron emitting filament |

| Operating pressure | 1 × 10 -11 mbar ….1 × 10 -5 mbar |

| Acceleration voltage | 4 - 10 kV |

| Beam power | max. 10 kW, (3 kW; 5kW; depending on power supply) |

| Filament current | max. 50 A at 10 V (AC) |

| Spot size | 5 mm diameter, approx |

| Primary beam deflection | 270° by permanent magnet system |

| Dymamic beam deflection | coils wound from KAPTON TM -

isolated wire; x-deflection current: ± 3 A; y-deflection current: ± 3 A; deflection frequency: max. 150 Hz |

| Bakeout temperature | 200°C (all air side connectors removed) |

| Cooling | water cooling, connectors Swagelok TM

8mm (air side); water flow min 8 l/min at 3 bar |

| Crucibles | 40 cm³, 100 cm³, 160 cm³ or 1000 cm3 hearth volume |

| Options | water cooling hood with custom apertures integrated on base flange

(K); integrated custom-made source shutter (S) with optional drive unit LSM 40-100; integrated refill unit ERU 16 (R) |

Crucibles

The most commonly used crucible material is PBN; other materials are available as required. Please refer to the Selection Guide or inquire for detailed recommendations. For information on crucibles see Crucibles .

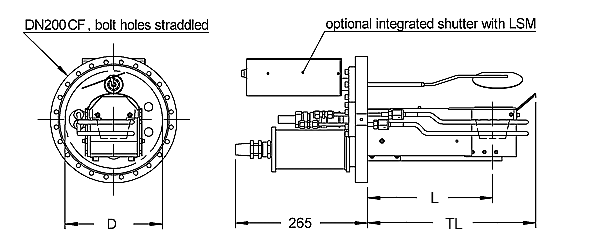

Dimensions

Specific data

For general information on CF mounting flanges see Flange and Gasketdimensions .

| Product | CF flange | Nominal capacity | Cooling | Shutter* | Refill unit | UHV dimensions*** [mm] (min. 250mm) | TL | typ. electrical [W]/[A] | Power supply product code | |

|---|---|---|---|---|---|---|---|---|---|---|

| [cm³] | [mm] / [mm] | [mm] | [kW] / [mA] | Product code | ||||||

| EBV | 150 - | 40 - | LxxxD195 | L+100 | 5 / 500 | HV | ||||

| EBV | 150 - | 100 - | LxxxD150 | L+85 | 5 / 500 | HV | ||||

| EBV | 200 - | 40 - | K | S* | LxxxD195 | L+100 | 5 / 500 | HV | ||

| EBV | 200 - | 100 - | K | S* | LxxxD195 | L+90 | 5 / 500 | HV | ||

| EBV | 250 - | 40 - | K | S* | LxxxD245 | L+100 | 5 / 500 | HV | ||

| EBV | 250 - | 100 - | K | S* | R** - | LxxxD245 | L+90 | 5 / 500 | HV | |

| EBV | 250 - | 160 - | K | S* | R** - | LxxxD245 | L+100 | 5 / 500 | HV | |

| EBV | 300 - | 1000 - | K | S* | R** - | LxxxD290 | L+100 | 10 / 1000 | HV |

* manual or automated shutter actuation (with LSM 40-100) ** Si recharge block Ø36x20, mass 45g *** specify UHV length L with order

Product code: e.g. EBV 200-40-KS-L250D195 is a standard electron beam evaporator on DN200 CF flange with 40cm³ hearth capacity, water cooling hood and integrated linear shutter, in-vacuum length 250mm and diameter 195mm.