- High-purity phosphorus (P2 ) source

- Simple and safe operation with non-inflammable GaP source material

- Compatible with most UHV and MBE systems

- Various crucibles from 10 to 420 cm³

- Precise and fast flux control with high reliability

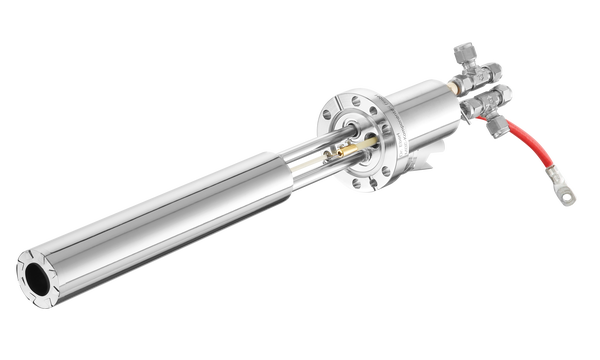

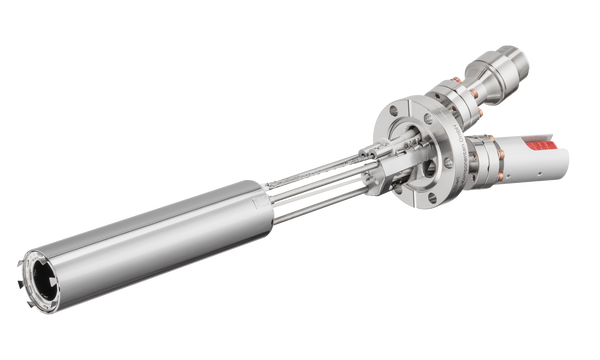

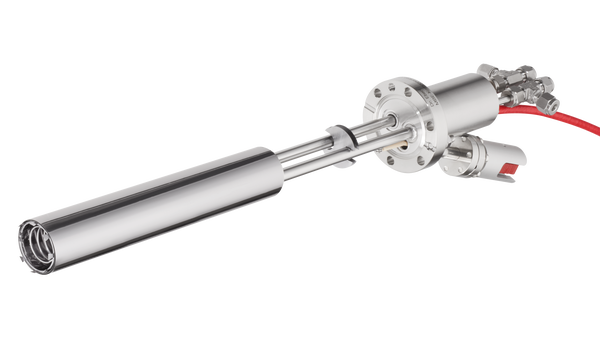

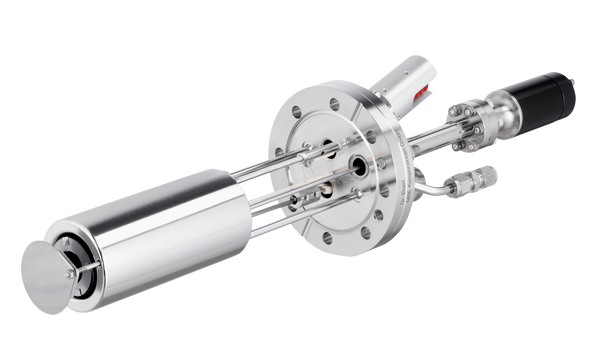

- Optional on-flange integrated cooling shroud and shutter

Introduction

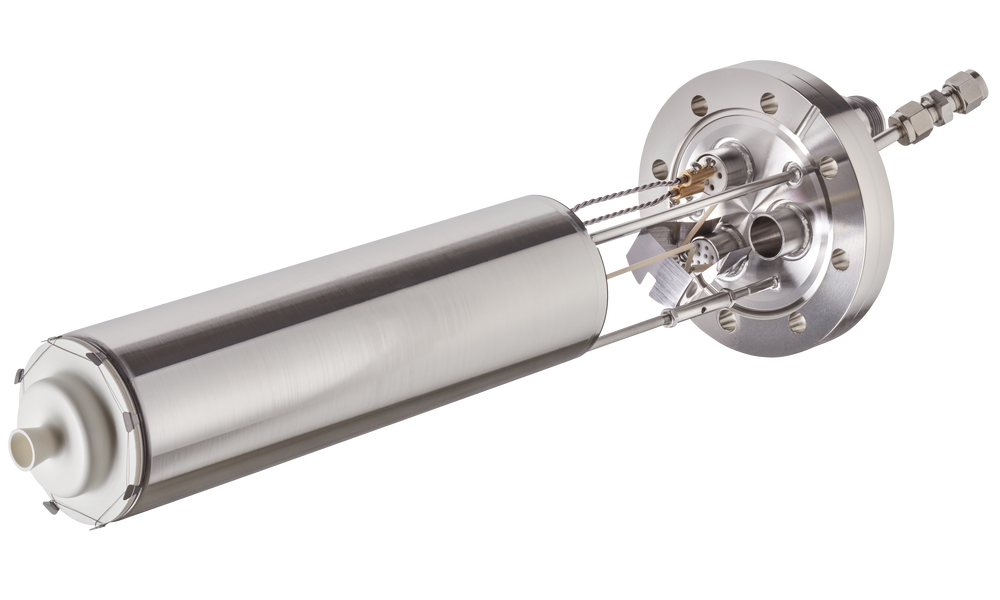

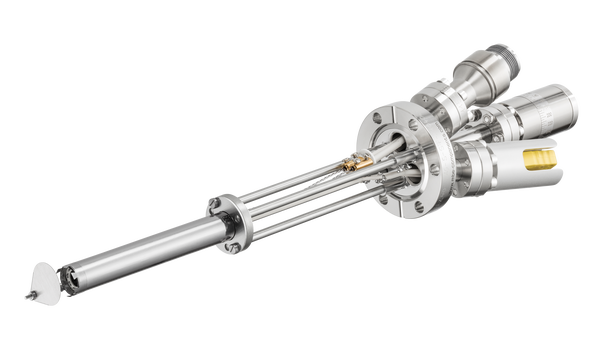

The Decomposition Source DECO is an ultra-pure source for P2 based on the decomposition of GaP. It is an affordable and easily operated alternative to valved phosphorus sources .

Adapted from WEZ and

PEZ effusion cells, the simple construction of

the DECO with its specially designed Ga-Trapping Cap Unit maintains the advantages

of easy installation, full compatibility to all MBE systems, high

reliability and low costs of ownership.

Operating the DECO is similar to usual effusion cells and does not

require any complicated mechanical valves or controllers. Compared

to frequently used valved phosporus crackers, the deposition of white

phosphorus (P4 ) in the growth chamber is significantly

reduced due to the direct generation of pure P2 from GaP.

Two main fields of application for the DECO have emerged: the source can be built for growth applications offering elevated evaporation rates and large crucible capacities, or optimized for special doping applications ( DECO-D ), e.g. phosphorus doping in Si MBE, with a reduced cell shutdown time.

The heater of the DECO consists of a Ta wire filament supported by PBN

rings, similar to standard effusion cells. This design guarantees

minimum outgassing at operation temperature in combination with

excellent reliability, long-term stability and extended lifetime.

PBN is invariably applied As crucible material for GaP decomposition.

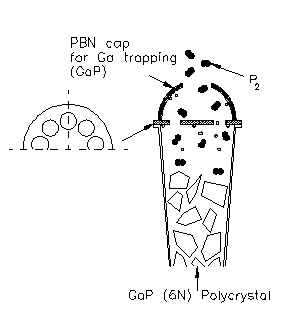

Ga-Trapping Cap Unit

The DECO source features a unique Ga-Trapping Cap Unit system which provides a very pure P2 beam by decomposition of GaP. The idea underlying that unit is the sublimation of phosphorus from GaP at rather moderate temperatures at which gallium has only a low vapor pressure. By special baffle plates parasitic Ga atoms are efficiently separated from the P2 beam, thus producing a very pure P 2 flux.

The Ga-Trapping Cap Unit is a simple but effective design consisting of only a small number of well-designed parts which are mounted onto the PBN crucible without additional tools or holders. For source maintenance and crucible refilling the unit is likewise easily removable.

Upon special request, a complete Ga-Trapping-Cap Unit is available as a

product of its own, for retrofitting standard effusion cells.

Inquire for further information on compatibility.

operating temperatures 900-1200°C for growth applications

precise adjustment of P2 incorporation into GaAsP. GalnAsP, etc., compound layers

P2/P4 ratio about 150 : 1

very low parasitic Ga flux (P : Ga > 105 );** ** (P : Ga > 103 without Ga-Trapping Cap Unit)

high efficiency: about 20 g P in GaP for 100µm film thickness

marginal white phosphorus accumulation in MBE system

no additional safety facilities needed in contrast to PH3 , AsH3 or valved elemental phosporus crackers

no bakeout necessary before opening the system

compatible with standard III/V solid source MBE

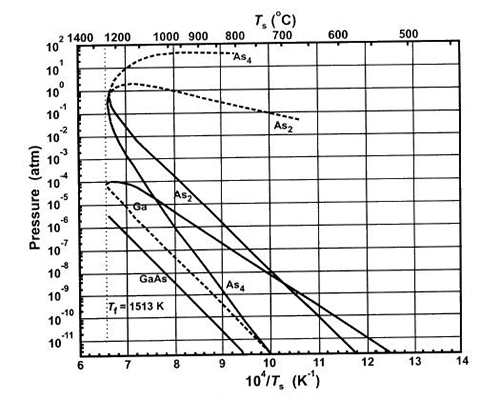

It is also possible to use the DECO as an As2 or Sb 2 source. The diagram below shows the analog curves for a Ga-As system. Please inquire for more information.

Application

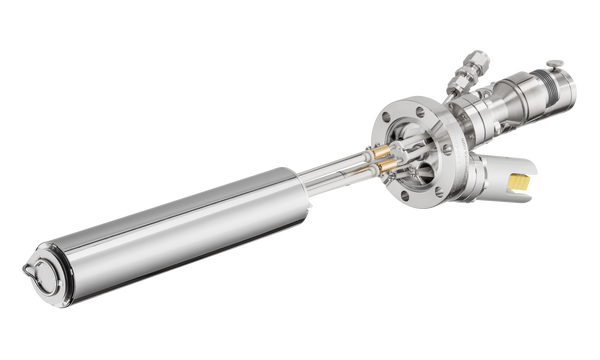

Typical applications of the DECO are the growth of phosphide compounds (GaInP, InP) in III-V MBE as well as Phosphorus (n-type) doping in Si MBE (with DECO-D , the cell that is explicitly optimized for doping applications). All WEZ standard effusion cells are in principle also available with Ga-Trapping Cap Unit. DECO sources thus combine a most efficient, well-proven heating system with the unique principle of GaP decomposition, which leads to a very stable and reproducible P 2 beam formation.

For growth applications the DECO is optimized toward a high flux

rates, requiring relatively high operation temperatures and a large

orifice of the cap. For these sources a maximum crucible volume is

typically chosen to allow extended growth campaigns.

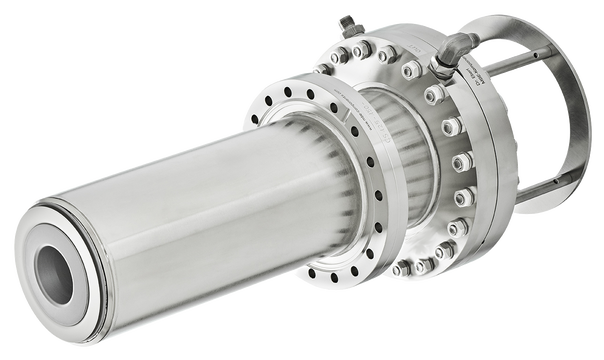

For phosphorus evaporation in large-scale and professional MBE systems,

please see the Valved GaP Compound Source

VGCS that offers larger capacities and even

faster flux control.

Single crystal GaP source material with a purity >6N is offered together with the source.

References

There are several publications based on phosphorus growth with DECO sources.

Technical Data

| Filament type | Ta wire heating filament |

| Thermocouple | W5%Re/W26%Re (type C) (type K on request) |

| Operating temperature | 900-1200°C for growth applications |

| Outgassing temperature | 1500°C |

| Bakeout temperature | 250°C |

| Cooling | integrated water cooling or separate cooling shroud |

| Crucibles | 10-420 cm³ PBN crucibles |

| Options | integrated water cooling ( K ), integrated rotary shutter ( S ) |

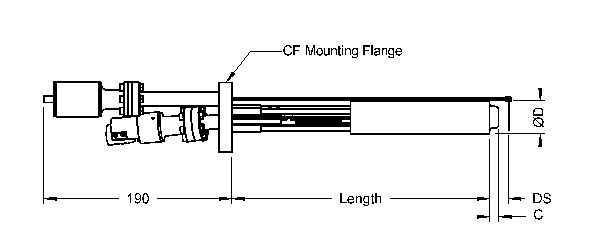

Dimensions

Specific data

For general information on CF mounting flanges see Flange and Gasketdimensions .

| Product | CF flange | Nominal capacity | Lip diameter | Cooling | Shutter* | Thermocouple | Crucible material** | UHV dimensions*** [mm] | max. electrical [W]/[A] | Power supply product code | Crucible product code | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [cm³] | [mm] | Type | [mm] / [mm] | [W] / [A] | Product code | Product code | ||||||

| DECO | 40 - | 10 - | 22 - | S - | C - | P - | LxxxD34 | 120 / 6 | PS 30-10 | CRU 10-22 | ||

| DECO | 40 - | 10 - | 22 - | K | S - | C - | P - | LxxxD36 | 120 / 6 | PS 30-10 | CRU 10-22 | |

| DECO | 40 - | 35 - | 34 - | S - | C - | P - | LxxxD35 | 180 / 7 | PS 30-10 | CRU 35-34 | ||

| DECO | 40 - | 60 - | 37 - | C - | P - | LxxxD38 | 520 / 13 | PS 40-19 | CRU 60-37 | |||

| DECO | 63 - | 35 - | 34 - | K | S - | C - | P - | LxxxD60 | 450 / 12 | PS 40-19 | CRU 35-34 | |

| DECO | 63 - | 125 - | 54 - | S - | C - | P - | LxxxD55 | 800 / 14 | PS 80-19 | CRU 125-54 | ||

| DECO | 63 - | 130 - | 54 - | S - | C - | P - | LxxxD55 | 800 / 14 | PS 80-19 | CRU 130-54 | ||

| DECO | 63 - | 200 - | 58 - | C - | P - | LxxxD58 | 1280 / 16 | PS 80-19 | CRU 200-58 | |||

| DECO | 100 - | 420 - | 84 - | C - | P - | LxxxD84 | 800 / 12 | PS 80-19 | CRU 420-84 |

* rotary shutter possible on same flange ** PBN standard *** specify UHV length L with order

Product code: e.g. DECO 40-10-22-KS-C-L277D36 is a GaP compound source on DN40 CF-flange for a 10cm³ crucible (lip Ø 22), integrated water cooling shroud, shutter, type C thermocouple, in-vacuum length 277mm and diameter.