- Clean operation in UHV up to 2000°C

- Excellent beam uniformity for doping and layer growth applications

- Flat pyrolytic graphite or tungsten wire filaments

- Wide opening crucibles with capacities from 5 to 200 cm³

- Various crucible materials

- No ceramic parts in the hot zone

Introduction

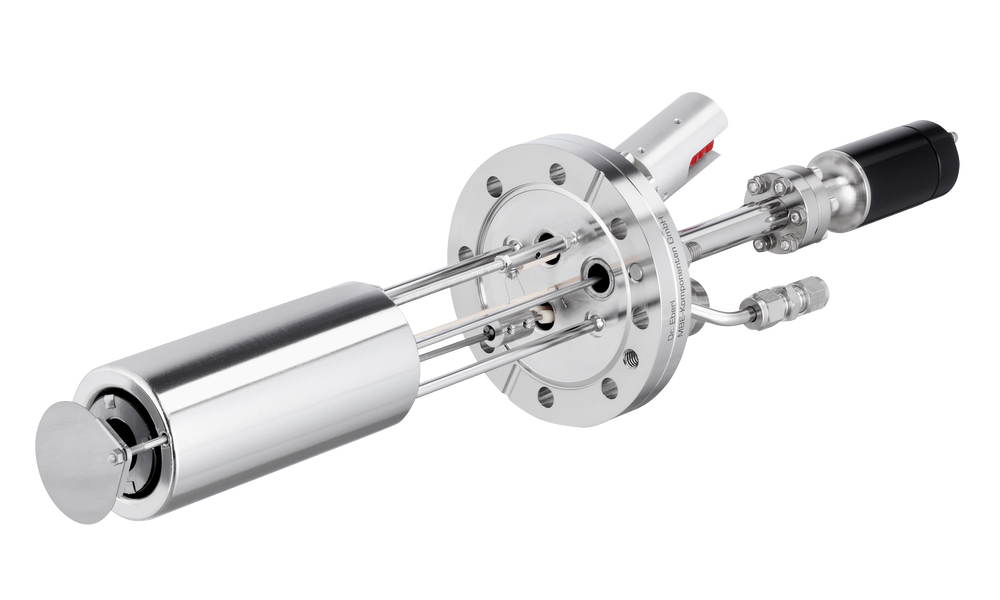

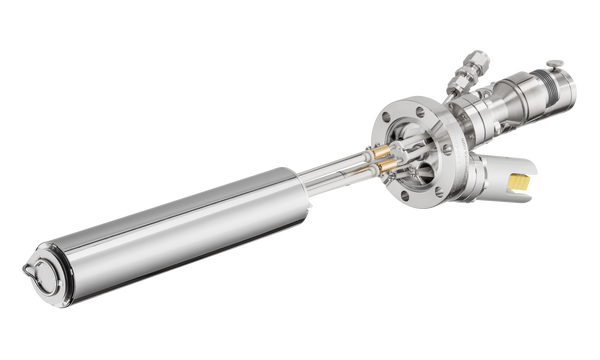

The High Temperature Source HTS allows evaporation of high vapor pressure materials, thereby combining very uniform material deposition with high flux rates. This is accomplished by heating a shallow crucible with wide opening up to a maximum temperature of 2000°C. Typical applications are boron doping or Ge evaporation in Si MBE.

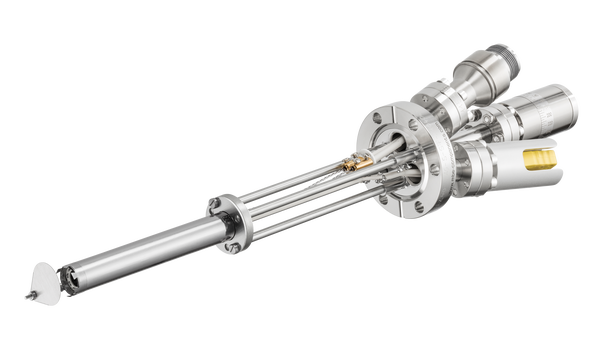

HTS sources feature a flat filament situated below the crucible. The short length of the crucibles and an effective shielding of the heater assembly provide for a sufficiently uniform heat distribution within the crucible.

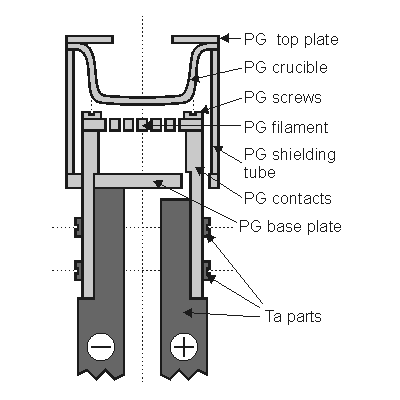

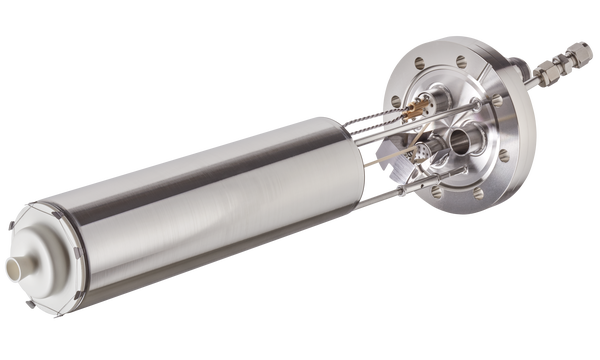

The “classic” HTS is equipped with a free-standing pyrolytic graphite (PG) filament and is primarily used in Si MBE. Its design is derived from the concept of the carbon sublimation source SUKO . Filament and crucible are completely surrounded by PG parts (screws, washers, contacts, top plate and shielding tube) that protect the hot filament. No ceramic or metal parts are used in the hottest zone as these can outgas significant amounts of CO and other undesirable residual gases.

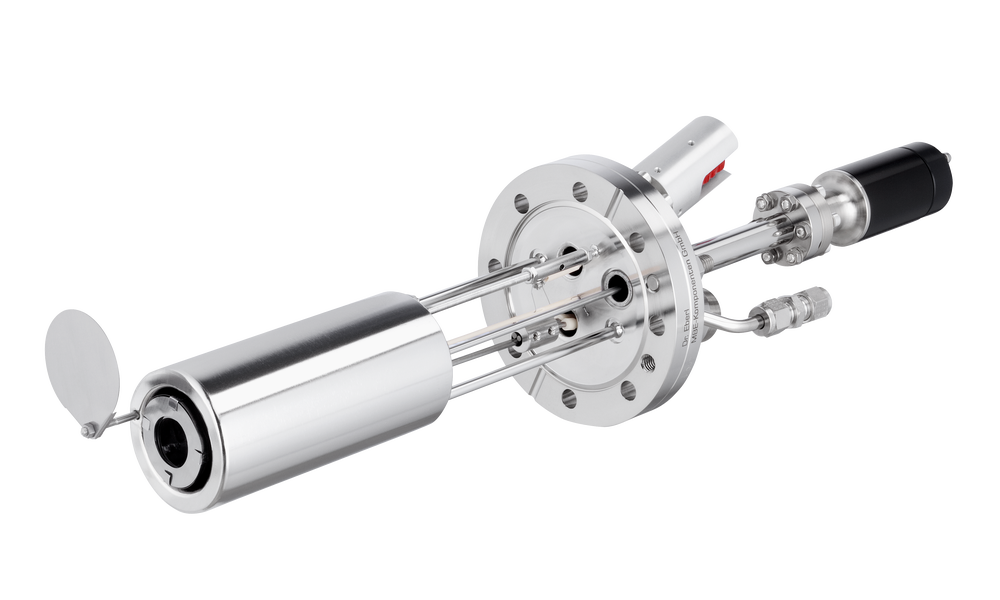

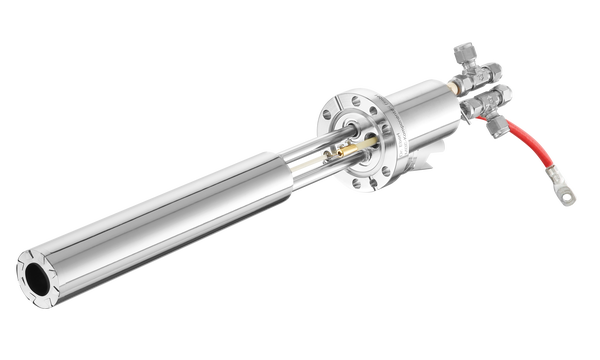

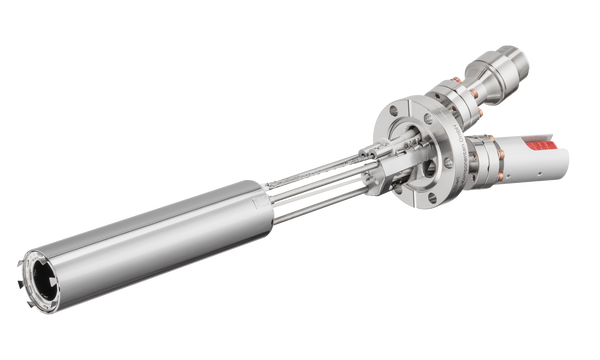

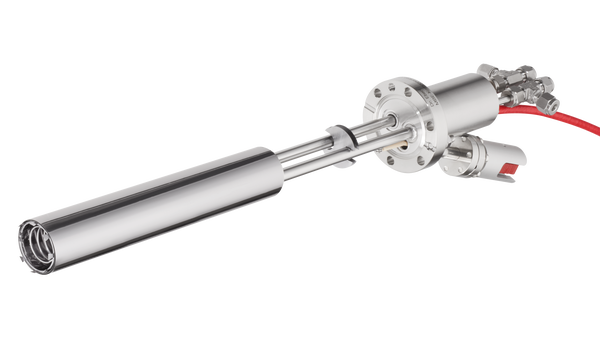

The models labeled HTS-W are a later development, especially designed for high temperature boron doping and the evaporation of low vapor pressure metals. Instead of graphite parts the HTS-W uses a meander-shaped tungsten (W) wire filament that is fixed onto tantalum contacts. The heater is protected by extensive tantalum radiation shielding and shows an extended lifetime, since there is no gradual sublimation of the filament material. Periodic maintenance with replacement of PG parts is thus made redundant.

The pyrolytic graphite parts used in a HTS source are pictured on the right. For Ge evaporation in Si MBE the HTS is usually equipped with PBN or PG crucible and an additional Si orifice plate.

PG or tungsten crucibles are recommended for boron doping with the HTS-W.

It is self-evident that all HTS versions can also be applied for other materials. Due to the special shape of the crucibles, HTS sources should however be mounted close to vertical to take advantage of the full crucible volume (particularly if the evaporant gets liquid at operation temperature).

Application

Typical applications of the HTS/HTS-W are the sublimation of elemental boron for p-type doping in MBE or silicon solar cell research and evaporation of Ge in SiGe MBE.

In case the particular application demands the special properties of the HTS/HTS-W, it is also possible to use them with CaF2 , Ti, Ni, Cr, Au, Er, La, etc.

Results from p-type doping in Si MBE, using the HTS for sublimation of boron, are shown in the right-hand figure.

This diagram is a typical example for the boron doping concentration as a function of the electrical current and is based on data obtained with a HTS 63-25-50.

Technical Data

| Filament type | HTS: high purity pyrolytic graphite filament; HTS-W: flat two-layer tungsten wire filament |

| Filament shielding | HTS: filament completely shielded with PG parts; HTS-W: filament shielded with tantalum radiation shielding |

| Thermocouple | W5%Re/W26%Re (type C) |

| Operating temperature | max. 2000°C (1700°C for HTS 100) |

| Outgassing temperature | max. 2000°C (1700°C for HTS 100) |

| Bakeout temperature | 250°C |

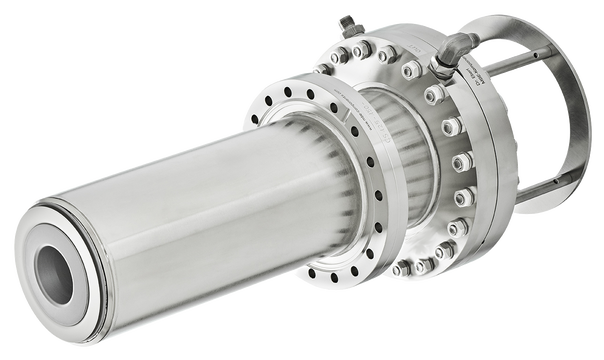

| Cooling | integrated water cooling or separate cooling shroud |

| Crucibles | 5, 25, 200 cm³; PG, W, PBN, BeO crucibles (other materials on request) |

| Options | integrated water cooling ( K ), integrated rotary shutter ( S ) |

Crucibles

Standard crucible sizes of the HTS are 5, 25, and 200 cm³. PG, BeO, PBN,

and W are commonly used crucible materials. The maximum operating

temperature may be reduced by the choice of the crucible, e.g. to1600°C

for PBN.

Please refer to the

Selection Guide or inquire for

detailed recommendations. For information on crucibles see

Crucibles .

The second number of the product code is the nominal crucible capacity [in cm³], the third number indicates the lip diameter of the crucible. Please specify the crucible material .

Dimensions

Specific data

For general information on CF mounting flanges see Flange and Gasketdimensions .

| Product | CF flange | Nominal capacity | Lip diameter | Cooling | Shutter* | Crucible material** | UHV dimensions*** [mm] | max. electrical [W]/[A] | Power supply product code | Crucible product code | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| [cm³] | [mm] | [mm] / [mm] | [W] / [A] | Product code | Product code | ||||||

| HTS | 40 - | 5 - | 30 - | G - | LxxxD36 | 515 / 80 | PS 15-100 | CRU 5-30 | |||

| HTS | 63 - | 25 - | 50 - | S - | G - | LxxxD56 | 890 / 90 | PS 15-100 | CRU 25-50 | ||

| HTS | 100 - | 200 - | 102 - | G - | LxxxD106 | 3200 / 80 | PS 60-100 | CRU 200-102 | |||

| HTS-W | 40 - | 5 - | 30 - | G - | LxxxD36 | 470 / 20 | PS 35-24 | CRU 5-30 | |||

| HTS-W | 63 - | 5 - | 30 - | K | S - | G - | LxxxD57 | 445 / 20 | PS 35-24 | CRU 5-30 |

* rotary shutter possible on same flange ** no standard, inquire for your particular solution *** specify UHV length L with order

Product code: e.g. HTS 63-25-50-S-G-L300D56 a high temperature source (with graphite filament) on DN63 CF-flange for a 25cm³ crucible (lip Ø 50mm), with integrated shutter, PG crucible, in-vacuum length 300mm and diameter 56mm.