- Thermal sublimation of silicon from high purity intrinsic or highly doped Si filament

- Excellent growth of thin silicon layers

- Compatible with most MBE systems

- Water-cooled electrical contacts

- Inner filament shielding with pure silicon parts

- No ceramic parts in the hot zone Datasheet

Introduction

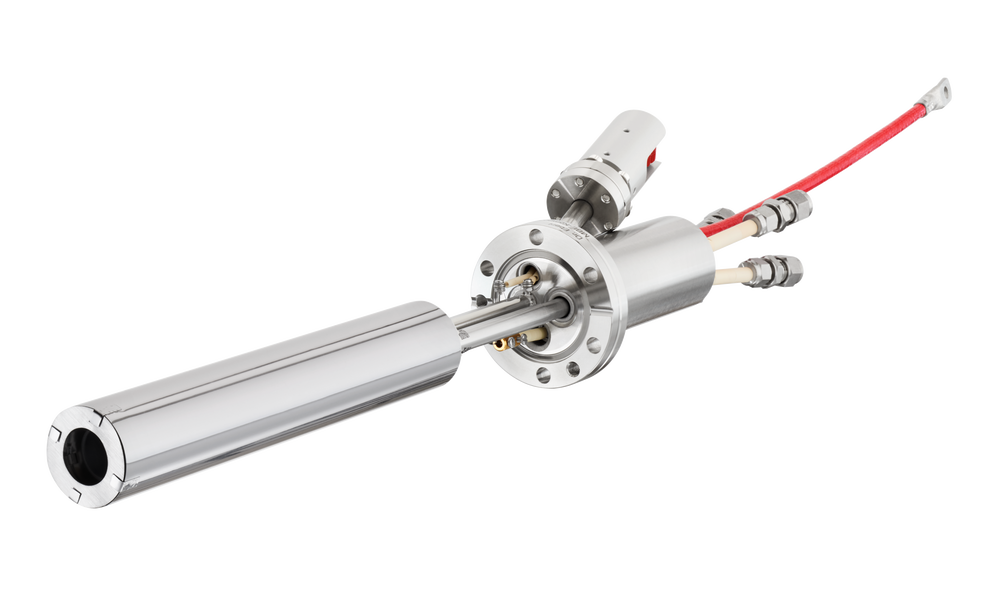

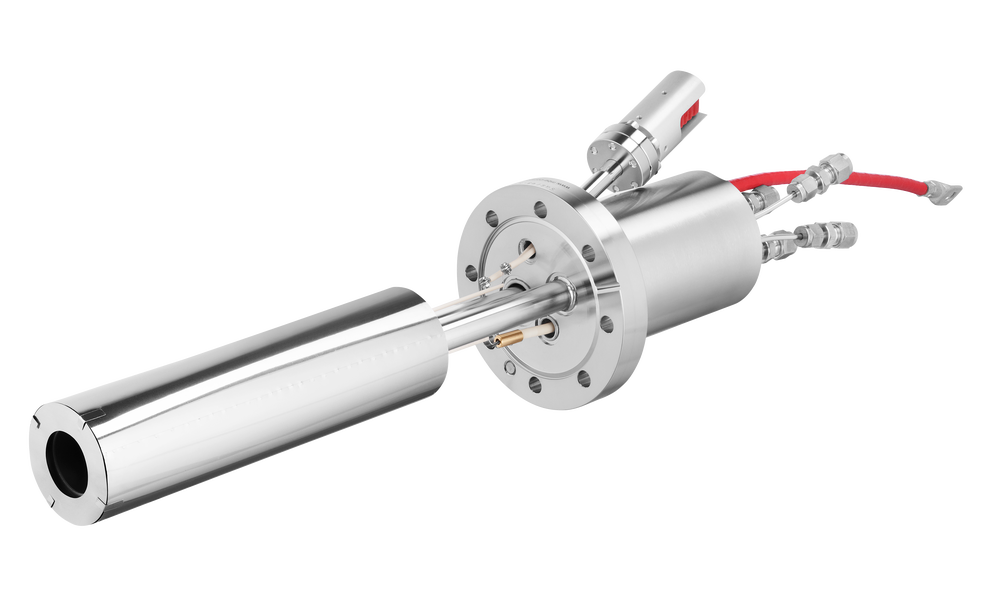

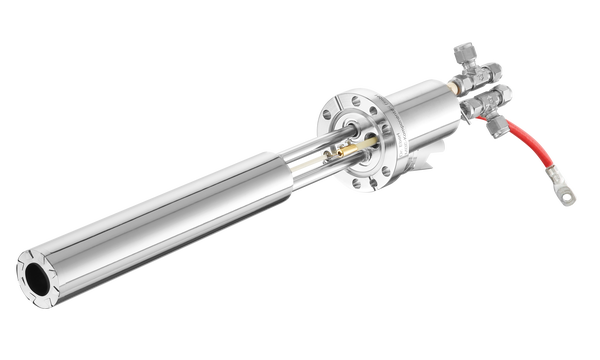

The Silicon Sublimation Source SUSI was developed for growing thin Si

layers, short period Si/Ge superlattices and Si/SiGe heterostructures.

It allows for growth of thin epitaxial Si layers with a crystal quality

not otherwise possible by evaporation from effusion cell crucibles.

The SUSI is also an optimal alternative to e-beam evaporators wherever

highest purity, utmost flux stability and low flux rates are required.

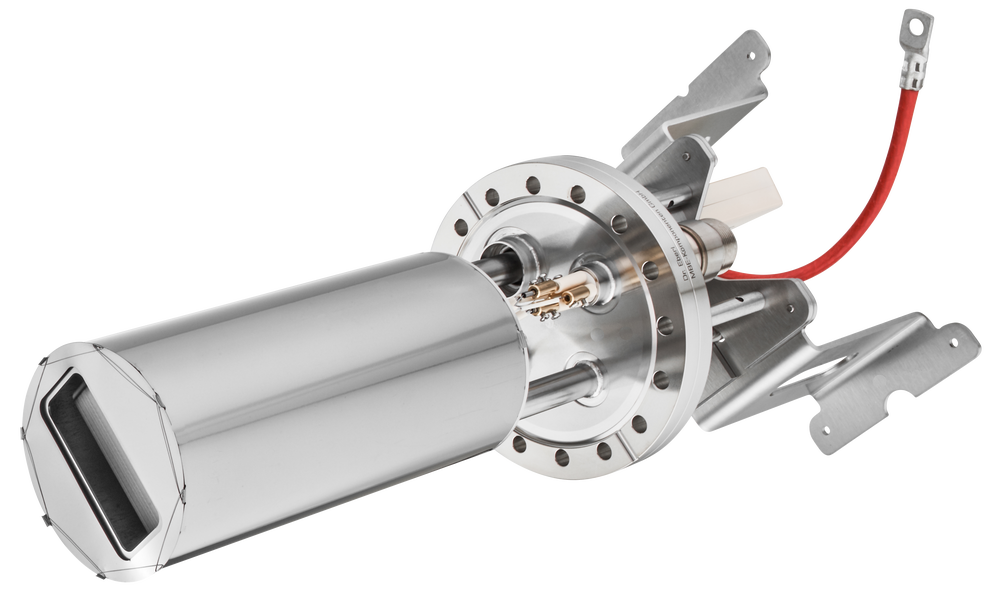

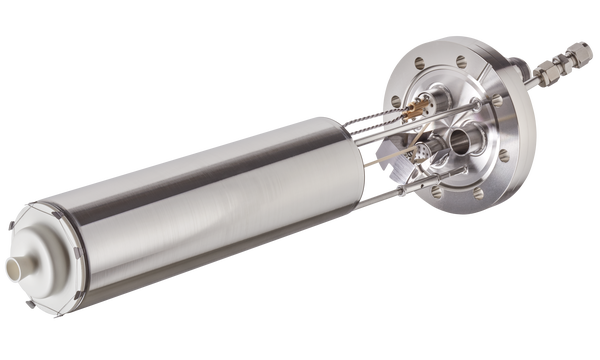

All main parts of the SUSI assembly (filament arch, base plate, shielding tube, and top plate) are made from high purity monocrystalline silicon.

Silicon sublimation from a solid filament provides a very clean and constant Si flux at a low growth rate level. Maximum growth rates of 7 Å/min and a total layer thickness of 5-10µm of pure Si with one filament are reported. The SUSI is therefore ideally suited for thin Si layer growth and doping in III-V MBE.

Among the various special applications of the SUSI are boron and phosphorus doping in Si MBE. In these cases the filament is machined from highly doped Si bulk material. See Application

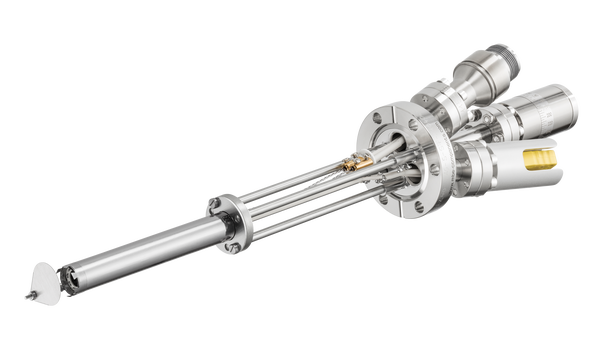

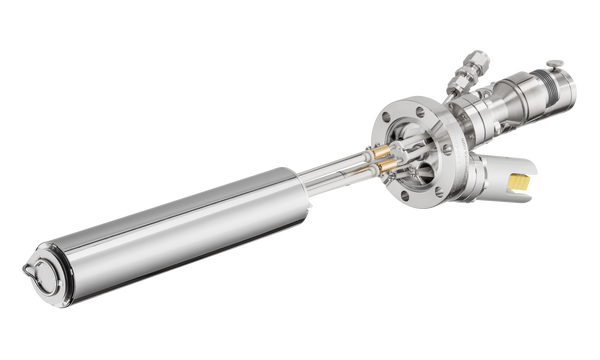

The most remarkable feature of the SUSI is its arch-shaped,

free-standing silicon filament, which is directly heated by electrical

current and exclusively surrounded by silicon shielding parts of highest

purity, effectively shielding the hot filament.

Extreme heating of any metal and ceramic parts is further avoided by a

very effective water cooling of the electrical contacts. Absolutely no

insulating ceramic parts are used in the hottest zone.

As the sublimating filament is totally surrounded by Si shielding parts the SUSI provides an extremely clean Si flux. In a well-designed Si MBE chamber a pressure in the 10-10 Torr range is achieved while running the SUSI at maximum growth rate.

Application

The SUSI is used for Si epitaxy (especially growth of high quality thin Si layers), Si doping in III-V MBE and doping in Si MBE. (For Silicon Sublimation Sources more optimized for doping applications please refer to our specialized source type SUSI-D .)

Si epitaxy and growth of thin Si layers

Compared to widely used e-beam evaporators, the SUSI is the superior Si source wherever highest purity, stable flux and an absolutely ion-free beam is required. Due to the low growth rate the SUSI is an ideal source for high quality thin Si layers, whereas it is naturally less suited to growing of thick layers.

The maximum total thickness of the films that can be grown with one SUSI 40 filament is about 2µm (5µm with SUSI 63) at a substrate distance of 100mm.

| e-beam evaporator | SUSI | effusion cell | |

| purity | + | + | - |

| flux control | 0 | + | + |

| flux rate | + | 0 | - |

Si Doping in III-V MBE

For doping in III-V MBE the typically required silicon flux is considerably lower than 0.1 Å/min. The electrical current needed for providing this flux rate is between 20 to 35 A for SUSI 40 and 40 to 50 A for SUSI 63. These values may be used as a reference point to start calibration of the doping level as a function of the current. The low power operation guarantees a long lifetime without any servicing.

Doping in Si MBE

A very special application is doping in Si MBE growth by using highly boron or phosphorus doped silicon filaments. Adjusting of the doping level is performed by changing the ratio of the flux rates between undoped silicon source and the boron / phosphorus doped silicon from the SUSI. There is no practical limit for very low doping levels, since the ratio between the undoped silicon source and boron doped silicon from the SUSI can be changed very easily and quickly over a wide range by changing the SUSI operation parameters.

For boron doping the source material is B doped to about 10 20 cm-3 . The maximum boron concentration in the epitaxial film is about 2x1019 cm-3 (during silicon sublimation some boron segregates on the surface of the silicon filament).

For phosphorus doping the source material is P doped to about (3-4)x1019 cm-3 .

Several Publications base on samples grown with SUSI.

Operation and Results

The figure on the right compares the growth rates of SUSI 40 and SUSI 63, measured as a function of the electrical current through a new silicon filament.

Over the operation time the filament becomes thinner, whereby the growth rates at a given current gradually increases. The current settings should therefore be reduced from time to time to keep the flux rate constant.

The lifetime of a silicon filament strongly depends on the control of the flux rate. This is especially important when operating at higher flux rates. A runaway increase of the flux rate can result in premature burning out of the filament.

The next figure shows the RHEED oscillations measured during Si homoepitaxy on a (001) oriented silicon substrate at 20keV electron energy and a substrate temperature of 400°C.

From the RHEED oscillation diagram a growth rate of 1.22 monolayers per minute (1.66 Å/min) can be determined. The low decay of the oscillation amplitude indicates ultra pure growth conditions.

References

Several publications based on samples grown with SUSI are listed in section References / List of Publications.

Technical Data

| Filament type | high purity monocrystalline silicon filament ρ>1000 Ω*cm (highly doped silicon on request) |

| Filament shielding | filament completely shielded with silicon parts |

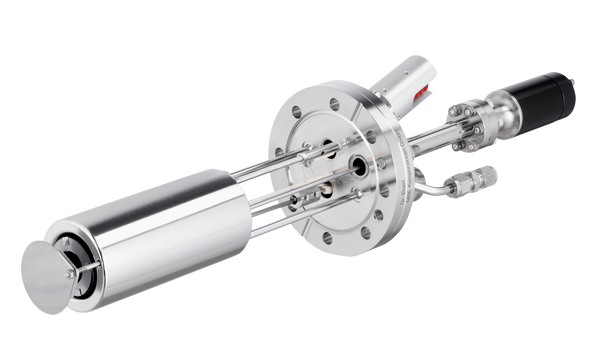

| Thermocouple | W5%Re/W26Re (type C) |

| Operating temperature | max. filament temperature 1400°C (limited by Si melting point) |

| Bakeout temperature | 250°C |

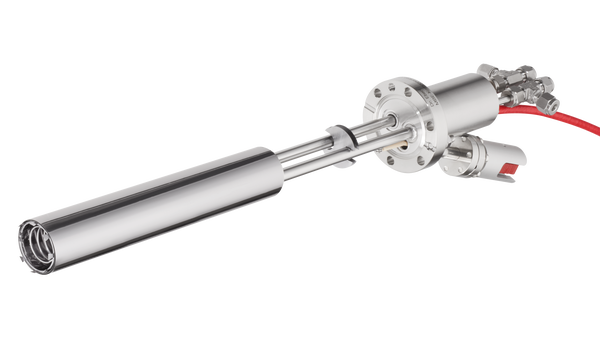

| Electrical contacts | water-cooled (4x Swagelok fitting connection O.D. 6mm); water flow min. 30 l/h |

| Cooling | separate water (or LN2 ) cooling shroud |

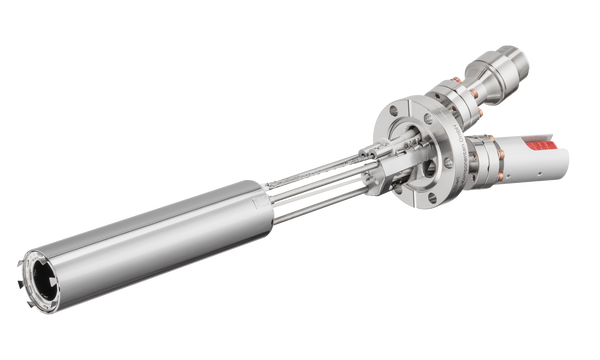

| Options | integrated rotary shutter ( S ) |

Dimensions

Specific data

For general information on CF mounting flanges see Flange and Gasketdimensions .

| Product | CF flange | Shutter* | UHV dimensions*** [mm] | max. electrical [W]/[A] | Growth rate** | Power supply product code | |

|---|---|---|---|---|---|---|---|

| [mm] / [mm] | [W] / [A] | [Å/min] | Product code | ||||

| SUSI | 40 - | LxxxD36 | 255 / 55 | 2 | PS 20-76 | ||

| SUSI | 63 - | S - | LxxxD55 | 405 / 80 | 7 | PS 15-100 | |

| SUSI | 100 - | LxxxD95 | 1100 / 145 | 18 | PS 20-165 |

* rotary shutter possible on same flange ** maximum growth rate at 100 mm distance *** specify UHV length L with order

Product code: e.g. SUSI 63-S-L310D55 is a silicon sublimation source on DN63 CF-flange with shutter, in-vacuum length 310 mm and diameter 55 mm.