- Full PBN solution for corrosive materials like Te, Sb, Se, As, Zn and Mg

- DN40CF ( O.D. 2.75" ) mounting flange c ompatible with all MBE systems

- Thermal cracking up to 1300°C

- 130 cm3 PBN reservoir

- Excellent thermal isolation between low temperature reservoir and hot cracking zone

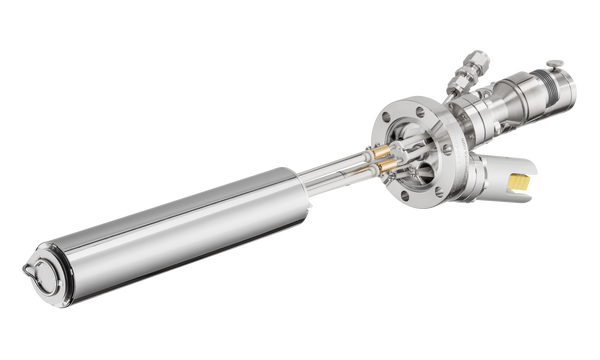

- Integrated water cooling for cracker stage

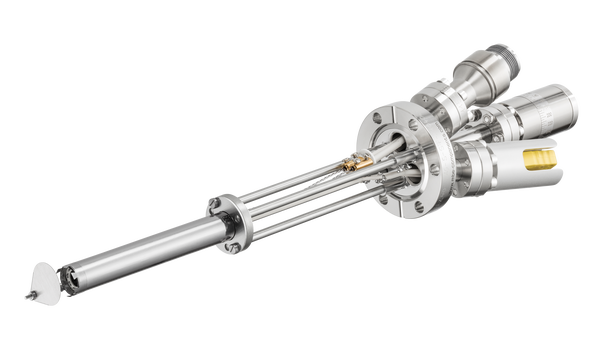

- Integrated rotary shutter (optional) Datasheet

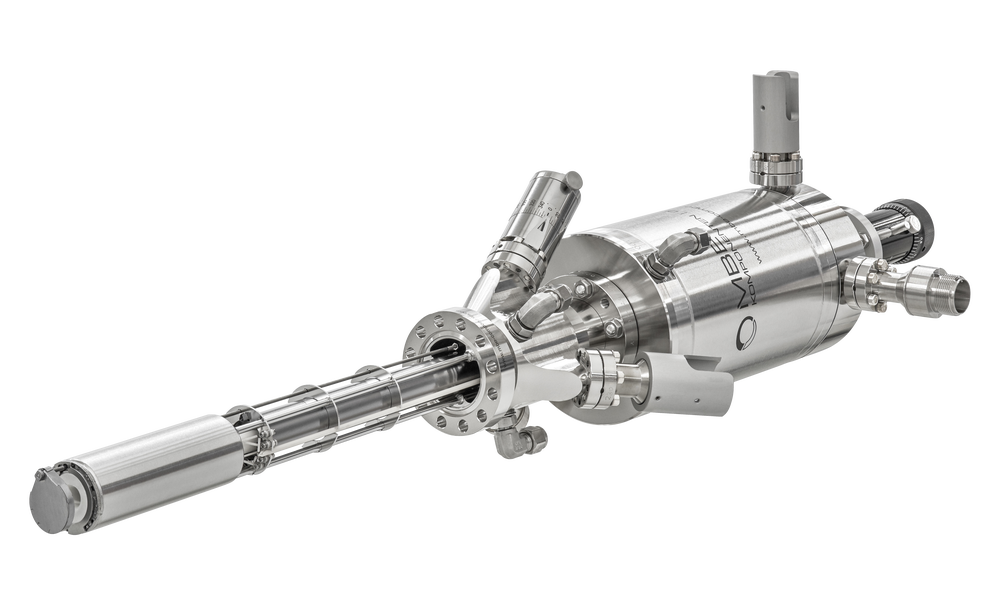

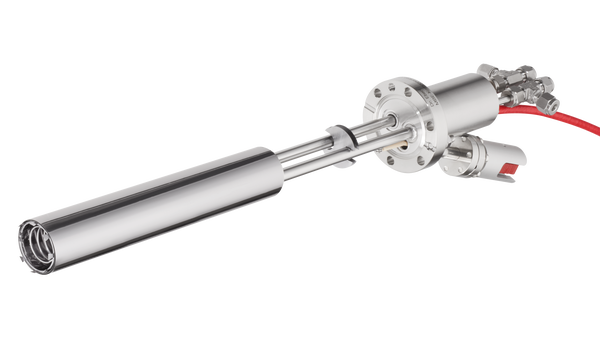

Introduction

The Valved Thermal Cracker Cell VTCC is a full PBN valved cell with a water cooled cracker stage. The compact design of the cell allows its implementation on the space-saving DN40CF (O.D. 2.75") flange.

It features a crucible size of 130 cm3 which is sufficient for most R&D applications.

The reservoir heater of the VTCC is designed to perform fast and precise ramps in the temperature range from 100°C to 650°C.

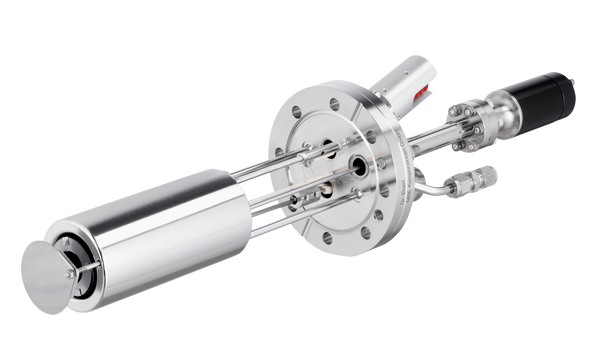

Three independent heating zones for reservoir, valve and cracker allow flexible adjustment of the cell operating conditions.

This, in combination with the full PBN construction of the valve, reservoir and cracker, enables a wide variety of the VTCC applications with the numerous high vapor pressure evaporation materials.

The crucible and cracker zones are shrouded by water cooling, minimizing the thermal load on the chamber.

The VTCC characteristics figure shows the example of the valve calibration, performed with Te. The valve demonstrates wide dynamic range, allowing precise flux adjustments in the % range of the maximal material flux.

The flux is reduced by about 5000 times when the PBN valve is closed. The VTCC may be equipped with the optional integrated shutter, with can be used to reduce the material flux even further.

The VTCC has excellent thermal insulation between the low temperature reservoir and the hot cracking stage.

Application

A source concept like this is used for high vapor pressure materials, which form atom clusters. Typical evaporation elements are As, Se, Sb, Te, Zn and Mg.

Technical Data

| General | |

| Mounting flange | DN40CF (O.D. 2.75") |

| In-vacuum length L | 287 mm |

| In-vacuum maximum total length TL | 307 mm |

| Maximum airside length OL | 507 mm |

| In-vacuum diameter D | 36 mm |

| Maximum airside radius AR | 134 mm |

| Shutter distance DS | 15 mm |

| Shutter opening angle | 90° ccw |

| Bakeout temperature | 200°C |

| Cooling water flow | 30-90 l/h |

| Weight | 15 kg |

| Maximum chamber pressure | 10-5 mbar |

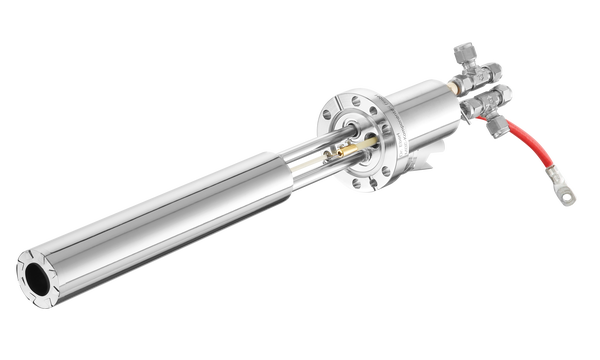

Reservoir | |

| Heater type | Ta wire filament |

| Thermocouple | NiCr/NiAl (type K) |

| Operating temperature | 100°C – 650°C |

| Outgassing temperature | Up to 700°C |

| Cooling | Integrated water cooling shroud |

| Crucible capacity | 130 cm3 |

| Crucible material | PBN |

Tube / Valve | |

| Heater type | Ta wire filament |

| Thermocouple | W5%Re/W26%/Re (type C) |

| Operating temperature | 200°C – 800°C |

| Outgassing temperature | Up to 850°C |

| Cooling | None |

| Tube material | PBN |

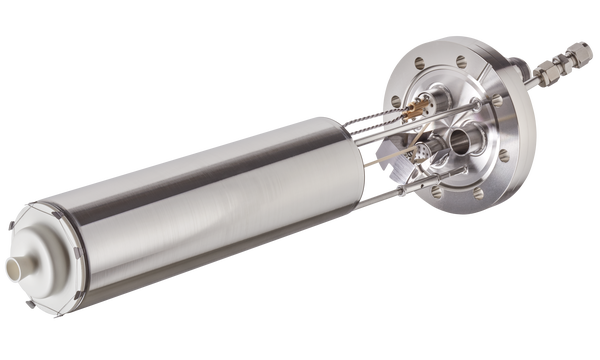

Cracker | |

| Heater type | Ta wire filament |

| Thermocouple | W5%Re/W26%/Re (type C) |

| Operating temperature | 300°C – 1200°C |

| Outgassing temperature | Up to 1300°C |

| Cooling | Integrated water cooling shroud |

| Cracking insert material | PBN |

Crucibles

The crucible material suitable for most evaporants is PBN. Please refer to the Selection Guide or inquire for detailed recommendations. For information on crucibles see Crucibles .

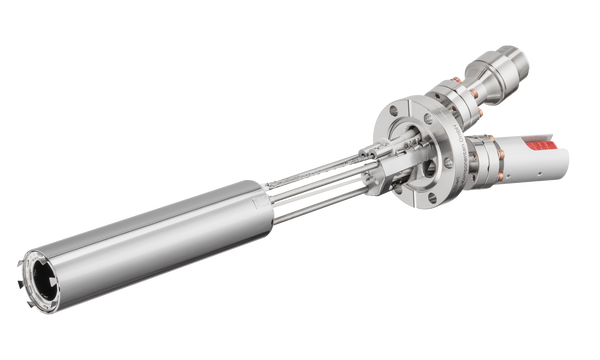

Dimensions

Specific data

For general information on CF mounting flanges see Flange and Gasketdimensions .

| Product | CF flange | Nominal capacity | Lip diameter | Cooling | Shutter* | UHV dimensions*** [mm] | max. electrical [W]/[A] | Power supply product code | Crucible product code | |

|---|---|---|---|---|---|---|---|---|---|---|

| [cm³] | [mm] | [mm]/[mm] | [W]/[A] | Product code | Product code | |||||

| VTCC | 40 - | 130 - | 54 - | K | S- | L287D36 | Reservoir 400/8 Valve 100/5 Cracker 150/8 | PS 60-10 PS 36-12 PS 36-12 | CRU 130-54 |

* rotary shutter possible on same flange *** UHV length L=287 mm

Product code:

e.g. VTCC 40-130-54-KS-L287D36

is a Valved Thermal Cracker Cell on DN40CF-flange for an 130 cm³ crucible (lip Ø 54 mm), with integrated water cooling shroud, shutter, PBN crucible, in-vacuum length 287 mm and outer diameter 36 mm.