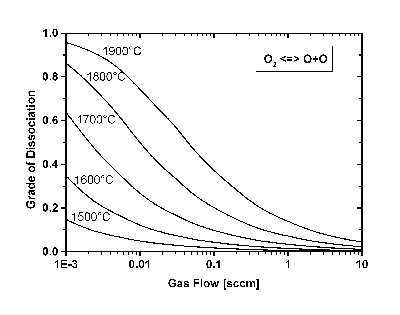

- O 2 dissociation up to more than 80%, depending on operation conditions

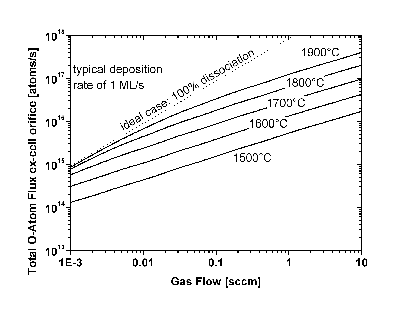

- Atomic oxygen flux density up to 1x10 15 /cm 2 s

- No high-energy particles and ions

- Low power consumption

- Integrated water cooling, low thermal load on other experimental equipment

- Optional customized aperture Datasheet

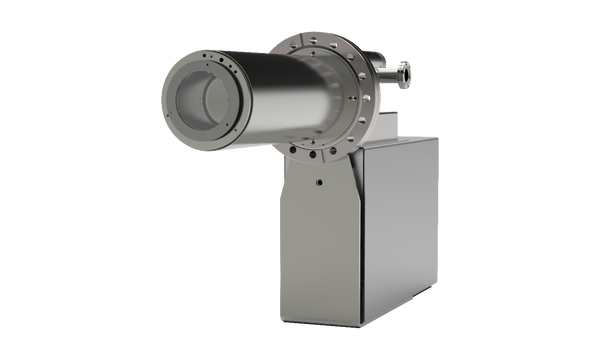

Introduction

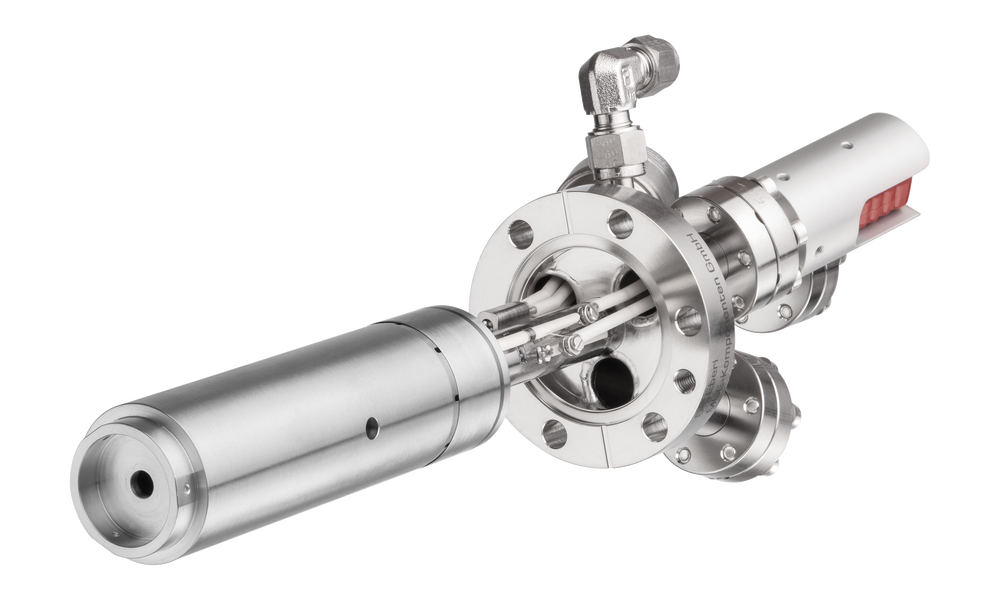

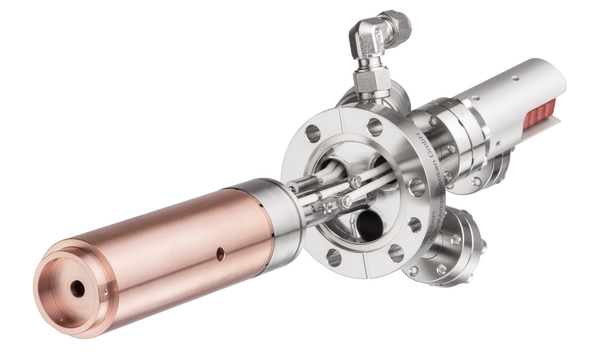

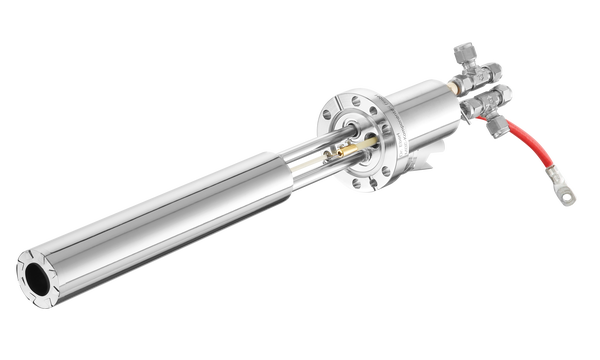

The Oxygen Atom Beam Source OBS is a thermal gas cracker that produces

an ion-free oxygen gas beam, thus avoiding ion induced damage to the

substrate. It features a very compact design and is easy to install and

to operate.

In contrast to oxygen plasma sources based on HF or HV ionization of gas

molecules, or gas sources heated by HV electron bombardment, the OBS is

heated by a DC operated filament, which surrounds a long cracking

tube.

Developed in collaboration with Dr. Karl Georg Tschersich of the

Institute of Bio- and Nanosystems (formerly Institute of Thin Films and

Interfaces) at Juelich Research, the OBS is an extensively tested and

well characterized oxygen source.

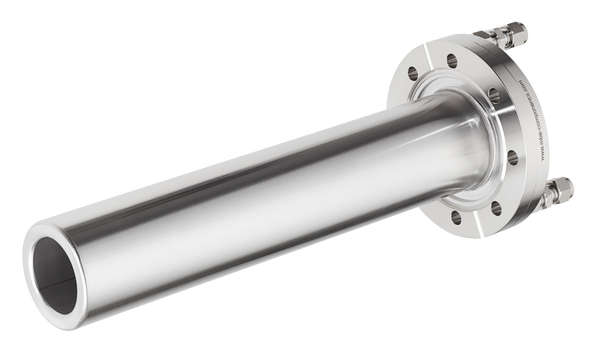

The intensity of the source can be controlled by the flow rate of oxygen and the heating power. The heating power determines the temperature of the cracking tube. Operation temperatures up to 1700°C provide an efficient thermal cracking of O 2 molecules within the tube.

The high purity cracking tube is the only part of the OBS directly exposed to the oxygen gas. It ejects a narrow angle distributed gas beam toward the specimen. The narrow beam of the OBS allows high atomic oxygen flux rates at the sample position, while keeping the O 2 background pressure of the chamber low as compared to plasma sources. Furthermore, the high cracking efficiency of up to 80%, which is available for low flux applications, reduces the chamber background pressure significantly as compared to ozone generators, with which the ozone concentration is limited to about 10-15%.

Despite the high temperatures needed for thermal gas cracking, the thermal load on the chamber is negligible, due to the integrated water cooling and use of a small diameter aperture (optional).

The following options are available:

- Usually the gas flow is regulated by a UHV leak valve or a mass flow controller which allow switching on and off the atom flux within several seconds. Short exposures can be terminated by a shutter which attenuates the oxygen atom flux down to the detection level.

- Oxygen atoms passing the sample and hitting the chamber walls can induce reactions detrimental to the experiment. A customized aperture is available which limits the solid angle of oxygen atom emission. Outside this angle no beam atoms could be detected by the QMA. Although tested so far with oxygen only, the source can be used as well as a radical beam source by decomposing other molecules at temperatures up to 1900°C.

Application

The use of a long, slender cracking tube results in a narrow angle

distribution of the atomic oxygen beam (typical FWHM: 10-30°) which

makes the OBS ideally suited for medium and low gas flux applications

(up to 0.1 sccm) on smaller sample sizes or long substrate distances.

Due to its highly efficient oxygen cracking mechanism and the resulting

low gas load on the vacuum system, the OBS can likewise be applied in

standard UHV, MBE, and ALD systems as a reliable, highly efficient and

low cost source for atomic oxygen.

Typical applications for the OBS are:

Oxide layer deposition

The OBS allows precise layer deposition of oxide layers, due to the fast

and easy control of the gas flow by shutter or UHV leak-valve.

Surface cleaning procedures

Atomic oxygen is used for removal of surface carbon contaminations.

Surface oxidation

In surface analysis applications as well as in ALD technology atomic

oxygen is used for the preparation of well defined oxide surface

layers.

Atomic spectroscopy of single atoms

The particle density of about 10 11 low energy O-atoms per cm 3 near the

cell exit allows a wide range of fundamental spectroscopic experiments

on single O-atoms.

Several publications to OBS are listed in section References / List of Publications .

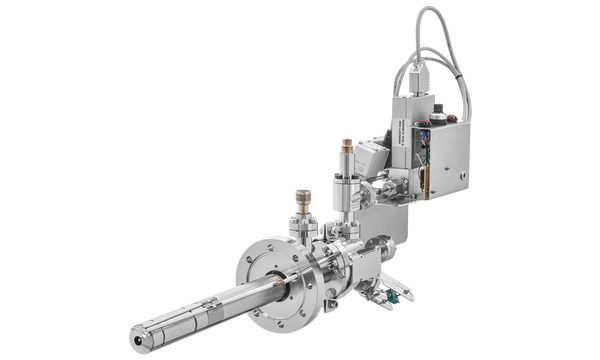

Gas Injection System

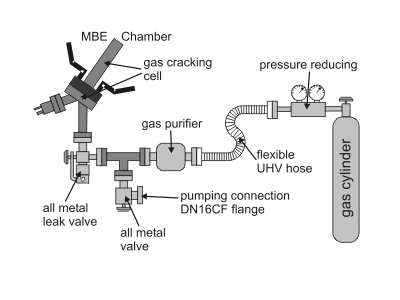

For optimized performance, we offer a complete gas injection system for

atomic oxygen. The gas injection system is completely assembled and only

an O2 gas cylinder is required to start operation. A simple

turbo molecular pump can be used to evacuate the O2 gas

line. The O2 gas line and all-metal leak valve can be baked

to 180°C.

Alternatively, the gas injection system can be equipped with a mass flow

controller (MFC) plus an all-metal valve instead of an all-metal UHV

leak valve. A mass flow controller in the gas line is preferred when the

OBS is used primarily for high intensity, long term runs, where mass

flow controllers require less attention due to their automated operation

compared to the gas feed setup above.

There are many different mass flow controllers on the market. It is

recommended that the customer provide the MFC. The maximum system

bake-out temperature depends on the specification of the MFC used.

- fully UHV compatible

- O 2 gas cracking cell

- all-metal UHV leak valve / mass flow controller (MFC) plus all-metal valve for shut-off during MFC maintenance

- all-metal valve for gas feed evacuation

- O 2 gas purifier

- flexible UHV tube 1m max. length

- bakeable system

- O 2 bottle and stainless steel

gas

pressure reducing regulator (not included)

Technical Data

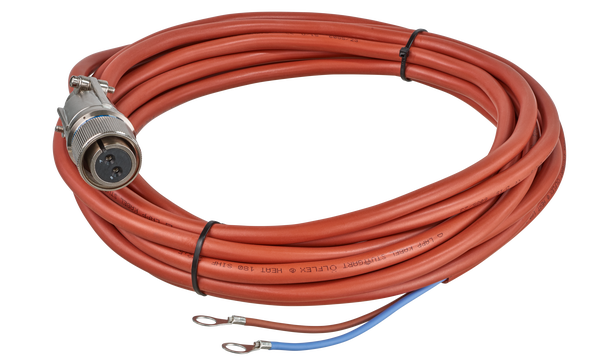

| Filament type | DC heated low voltage filament |

| Gas line | filament heated cracking tube |

| Thermocouple | W5%Re/W26%Re (type C) |

| Bakeout temperature | 250°C |

| Operating temperature | up to 1700ºC |

| Cooling | integrated water cooling |

| Accessories | aperture plate,leak valve |

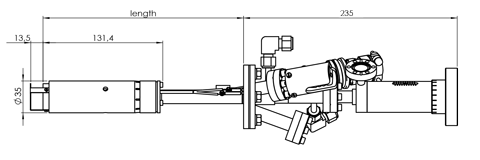

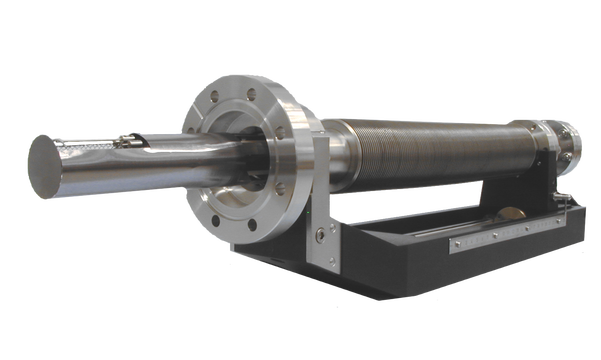

Dimensions

Specific data

For general information on CF mounting flanges see Flange and Gasketdimensions .

| Product | CF flange | UHV dimensions*** [mm] | Power supply product code | Filament current | Filament voltage |

|---|---|---|---|---|---|

| [mm] | [mm] / [mm] | [W] | [A] | [V] | |

| OBS | 40- | L190-400 / D36 | <200 | < 15 | < 15 |

*** specify UHV length L with order

Product code: e.g. OBS 40-L220D36 is an oxygen atom beam source on DN40CF flange with UHV-length 220 mm and in-vacuum diameter 36 mm.