- Uniform heating of substrates from small samples to 6 inch wafer diameter

- Wafer temperatures up to 1200°C

- Heater materials: Tungsten, Tantalum, Graphite, Silicon Carbide, Platinum, PBN encapsulated

- Special heaters for oxygen and reactive gas atmosphere

- Water-cooled ceramic bearings for continuous rotation

- Full adaptability to sample transfer by user-specific linear travel and custom sample holders

- Option for masked deposition: transferable wafer mask stage Datasheet

Introduction

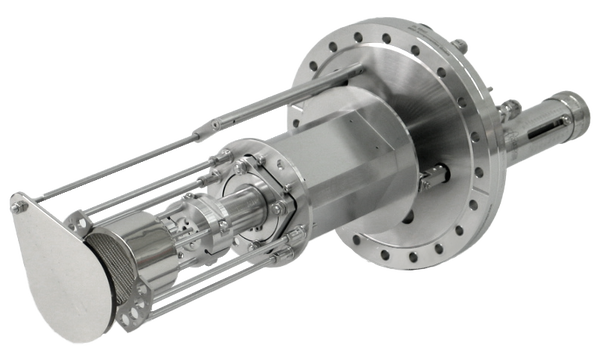

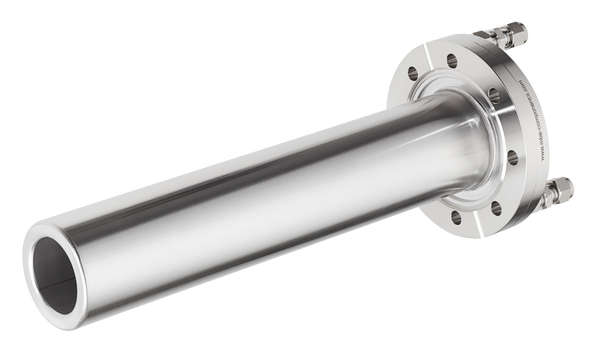

Substrate Manipulators SH meet the special requirements of MBE

applications, such as uniform and reproducible substrate heating,

trouble-free continuous rotation and, not least, clean and reliable

operation.

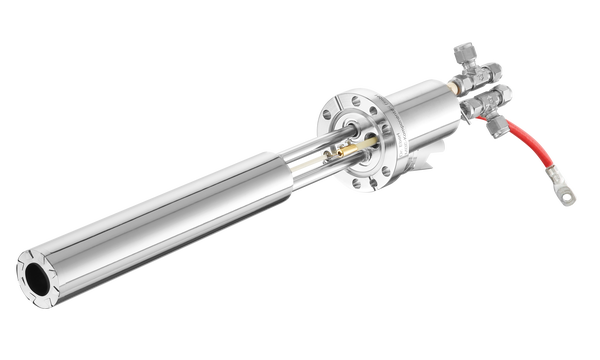

In III-V MBE manipulators with tungsten or tantalum wire heaters are typically applied, whereas graphite heaters are commonly used in SiGe MBE. Especially for oxide growth or other applications performed in a reactive gas atmosphere further heater materials are available, e.g. heaters from nickel or noble metal alloy wire, SiC heaters or heaters from PBN-embedded graphite.

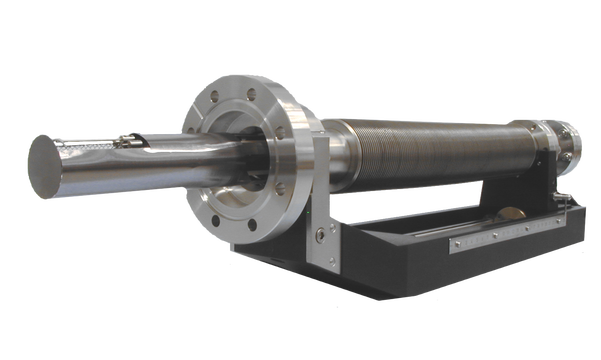

Careful selection of the construction materials and an optimized design are the prerequisite for long-term failure-free operation in all MBE and UHV systems. SH substrate manipulators are qualified for continuous long time sample rotation by using internally water-cooled ceramic bearings and magnetically coupled rotary motion feedthroughs. Both features account for the long and leak-free lifetime of the manipulator.

Usual rotation speed during growth is in the range of 10-30 RPM. A most precise substrate rotation and speed control is achieved with the Manipulator Control Unit MCU accessories kit, consisting of a suitable electric motor with motor holder and motor control unit. Alternativly the Programmable Manipulator Control Unit PMCU provides precise control of substrate rotation, substrate lift position (height) and angular substrate position by independant operation of two (or three) integrated stepper motors.

MBE systems from different suppliers use to have a lot of differing transfer mechanisms. For SH substrate manipulators a large number of wafer holder designs has therefore already been realized, while custom-made holders are always possible as needed.

The figures illustrate, for example, a special U-shaped molydenum wafer holder, a tantalum holder fitting to a Si wafer ring adapter and a heater with PBN diffusor. Solutions for standard Riber molybdenum wafer holders are also available.

SH substrate manipulators can, on request, be equipped with several options, such as integrated main shutter or electrically insulated wafer holders with bias feedthrough.

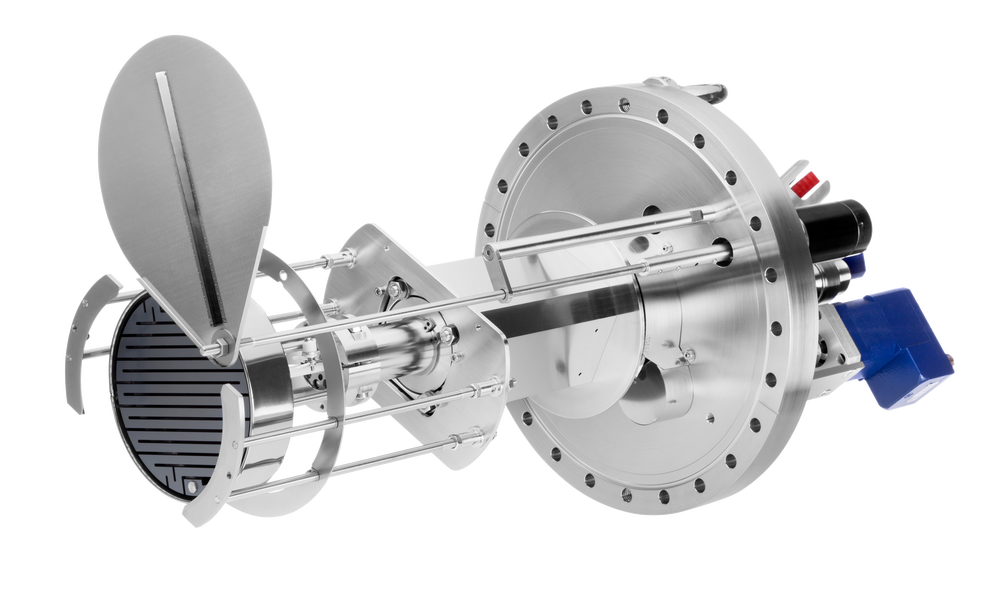

We also offer the option to transfer a mask closely spaced to the substrate. The lowest figure on the right side shows an example of a substrate manipulator with transferable mask holders. The mask can be transfered onto a special retainer which allows close positioning infront of the substrate wafer prior to material deposition through the mask. Subsequently the mask can be moved away from the substrate for further deposition steps without the mask.

Please contact us if you are interested in this mask option

For all applications requiring only substrate heating but no sample rotation, please refer to the wafer heaters WH.

Application

SH substrate manipulators are used in standard III-V MBE, GaN MBE, SiC growth and SiGe MBE. Manipulators with tungsten heaters are applicable for the majority of high temperature applications. In III-V MBE tantalum wire heaters are usually recommended, while SiGe MBE requires pyrolytic graphite heaters. All heater concepts provide clean UHV growth conditions even at elevated operating temperatures up to 1200°C.

Special SH versions designed for operation in oxygen rich environments

(up to several mbar) or reactive gas atmosphere are available and are

equipped with different kinds of heater materials, depening on the

particular application.

Note: It should be taken into account that at pressures above 10

-4 mbar the thermal conductivity of gases significantly

influences the heat transfer from heater to sample. When operating at

high temperatures and high pressure, it is strongly recommended to

contact our specialists.

Technical Data

| Heater type | tungsten wire (W), tantalum wire (T), pyrolytic graphite (G); (special heater materials like silicon carbide, platinum, pbn encapsulated on request) |

| Thermocouple | W5%Re/W26%Re (type C) (type K on request) |

| Wafer temperature | max. 900-1200°C (depending on heater material and application) |

| Bakeout temperature | 250°C |

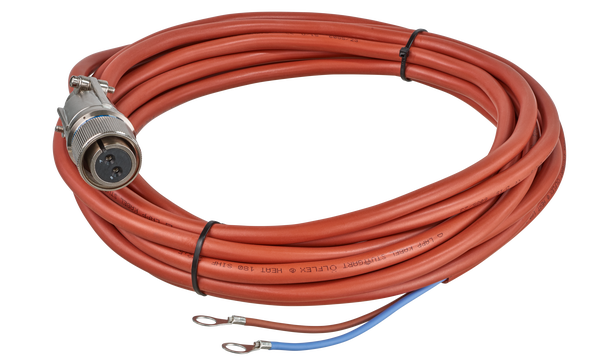

| Electrical contacts | copper-free contacts for metal heaters; water-cooled contacts for graphite heaters |

| Linear travel | 25mm standard, 30-50mm on request |

| Options | integrated main shutter ( S ), electrically

insulated wafer holder with additional feedthrough for bias voltage ( B ), tantalum wafer holder ( T ) |

Dimensions

Specific data

For general information on CF mounting flanges see Flange and Gasketdimensions .

| Product | CF flange | Substrate size | Heater material* | Linear travel** | Options | UHV dimensions*** [mm] | max. electrical [W]/[A] | Power supply product code | |

|---|---|---|---|---|---|---|---|---|---|

| [inch] | [mm] | [mm] / [mm] | [W] / [A] | Product code | |||||

| SH | 100 - | 2 | W T | 25 - | S, T - | LxxxD98 | 450 / 14 350 / 12 | PS 40-19 PS 40-19 | |

| SH | 150 - | 2 | W T G | 25 - | S, B, T - | LxxxD120 | 450 / 14 350 / 12 1200 / 60 | PS 40-19 PS 40-19 PS 15-100 | |

| SH | 150 - | 3 | W T G | 25 - | S, T - | LxxxD150 | 850 / 14 650 / 13 1500 / 60 | PS 80-19 PS 40-19 PS 15-100 | |

| SH | 150 - | 4 | W T G | 25 - | T - | LxxxD150 | 1200 / 16 850 / 14 1500 / 70 | PS 80-19 PS 80-19 PS 15-100 | |

| SH | 200 - | 4 | W T G | 25 - | S, B, T - | LxxxD200 | 1200 / 16 850 / 14 1500 / 70 | PS 80-19 PS 80-19 PS 15-100 | |

| SH | 250 - | 6 | W T | 25 - | S, B, T - | LxxxD250 | 2800 / 24 2800 / 24 | PS 120-25 PS 120-25 |

* other heater materials available for special applications ** user-specific linear travel on request *** specify UHV length L with order

Product code:

e.g. **SH 200-4G25-SB-L279D200

** is a substrate manipulator on DN200 CF-flange for 4 inch wafers, with pyrolytic graphite heater, 25mm linear travel for substrate transfer, integrated main shutter, additional bias feedthrough, in-vacuum length 279mm and diameter 200mm.