- Produces pure P 2 species (P 2 /P 4 > 150)

- Fast, stable and reproducible flux control

- Large crucible capacity of 420 cm 3

- Safe cell loading and operation

- Reliable large cross section cone valve

- No hot cracker zone

- Injector length and flux distribution adjustable to fit most MBE systems Datasheet

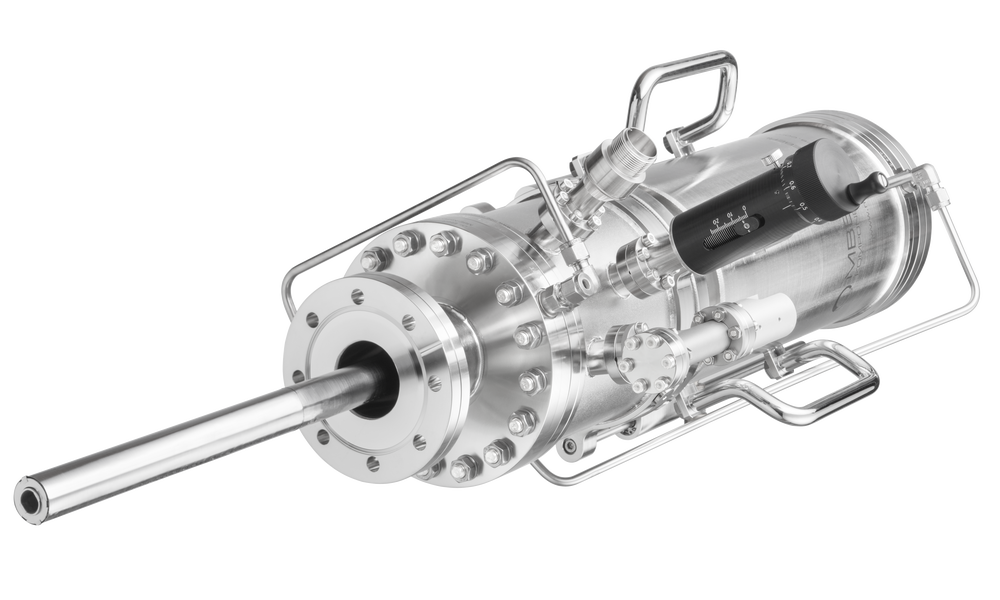

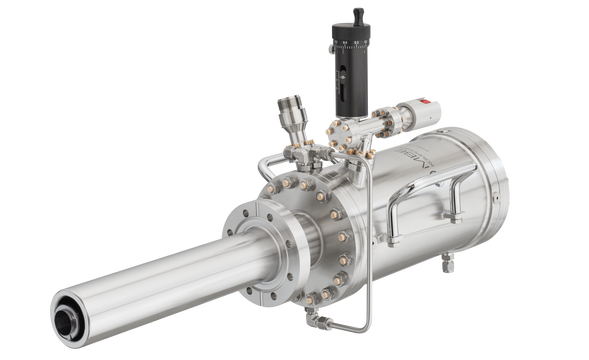

Introduction

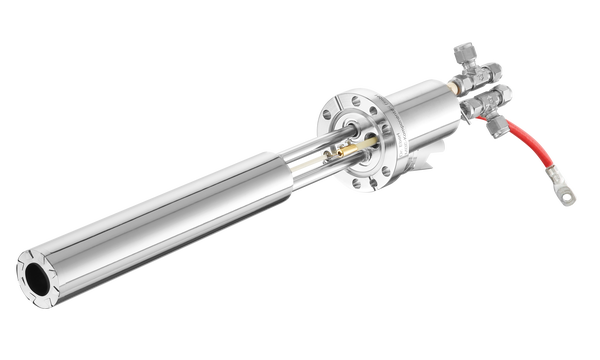

The Valved GaP Compound Source VGCS is a high purity P 2 -source, based on the decomposition of high purity GaP. The concept is derived from our DECO effusion cells to which a mechanical valve mechanism is added for rapid beam flux control.

Full MBE compatibility is reached by the integrated Gallium-Trapping-System, the integrated water cooling as well as the use of high purity inert materials such as pyrolytic boron nitride for all parts in the direct phosphorus path.

In contrast to sources using elemental phosphorus only minor amounts of

white phosphorus are formed within the cell and the formation of white

phosphorus within the MBE chamber is significantly reduced due to the

direct formation of P 2 species from

the decomposition of single crystal GaP chunks with purity 6N-7N.

Operation of the mechanical valve unit shows fast, stable and

reproducible flux control. Together with our valve controller easy

handling and integration to your MBE system is provided.

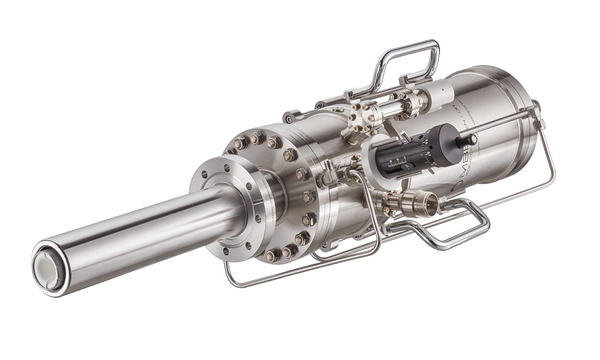

The design of the valve mechanism is schematically illustrated on the

right side. It provides a large cross section opening which allows very

good pumping of the GaP reservoir. The robust wide angle valve design

effectively elimitates the chance of locking, which is a frequently

observed problem for needle valves.

The VGCS has proven to be a very reliable P 2 source in the field and is compatible to commenly

used industrial and research MBE systems.

The figure on the right hand side shows the beam equivalent pressure

(BEP) at the substrate position measured as a function of the valve

position.

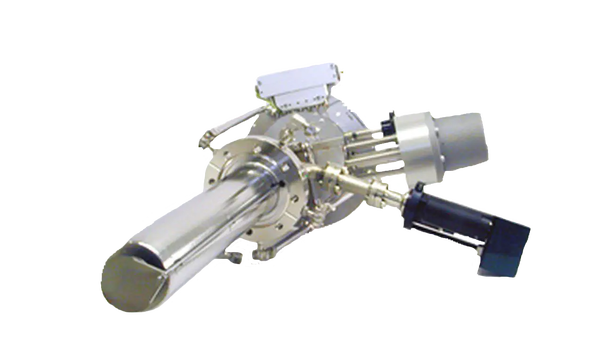

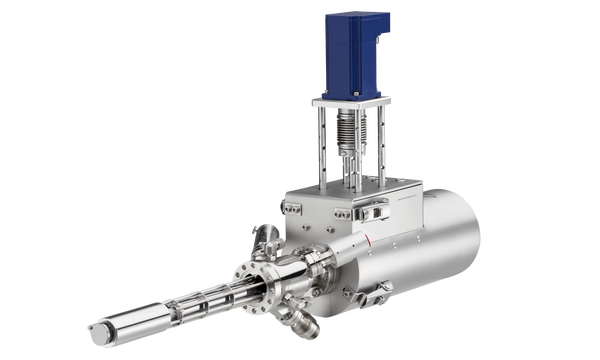

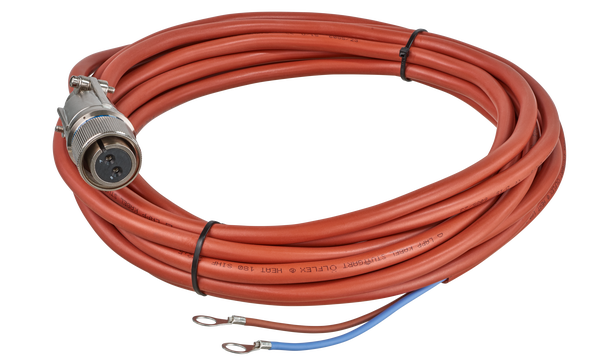

The Motorized Valve Control Unit MVCU is designed for operating the

valve of a valved source with a servo motor drive. Manual or remote

control with 0-10 V analogue input signal is possible. The display

indicates the linear position of the valve from 0 - 7.99 mm from fully

closed to fully open position. The servo motor drive has a resolution of

0.01 mm per step and a high motor speed of 10 mm/s. The automatic zero

calibration guarantees a highly reliable and reproducible operation of

the valve unit.

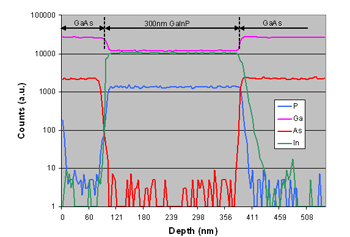

High purity of GaInP layers grown on GaAs is demonstrated by SIMS measurements. The contamination of the GaInP layer with oxygen and carbon is below the detection limit of about 5x10 16 cm -3 using highest purity single crystal GaP source material. The high performance of the phosphorus source allows growth of high quality GaInP/AlGaInP laser diodes or other P-compounds.

The P 2 pressure can be switched by

about two orders of magnitude. BEP during ramp up of the reservoir

temperature from 800 to 1000°C.

The flux can be adjusted within minutes, due to the high reservoir

temperature.

Application

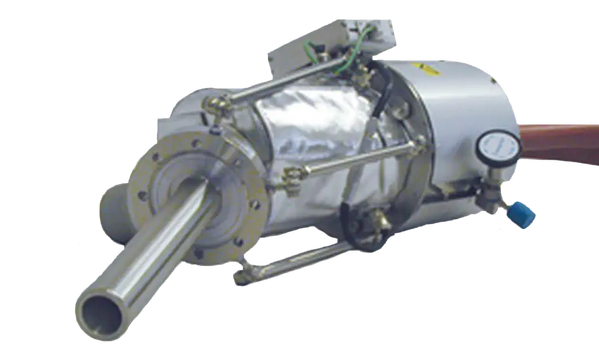

The VGCS is designed for growth of phosphide compounds in III-V-MBE. It

has been readily approved in industrial applications. The fast and

reproducible flux control using a valve allows the growth of

phosphide-arsenide heterostructures with very sharp interfaces like

quantum wells and superlattices. It is perfectly suited for applications

in HEMTs, HBTs, GaAlInP laser diodes and other devices. Also GaInP/InP

quantum dot lasers have been prepared. Moreover, very good results for

pseudomorphic high electron mobility transistors have been achieved.

The large crucible size makes the VGCS well suited for MBE research and

production systems.

The right picture shows red light emission from a GaAs/GaInP/AlInP laser diode grown and processed at the Max Planck Institute for Solid State Research in Stuttgart

Very sharp transitions of P are achieved by application of VGCS and

VACS sources at

one deposition run. 300nm GaInP are deposited on a GaAs buffer layer on

a (100) GaAs substrate. Due to the fast flux control properties of the

valve unit P is sharply reduced on the GaInP/GaAs interface as

demonstrated by the SIMS measurement on the right.

In return, the As concentration in the GaInP layer is at its detection

limit and three orders of magnitude below the GaAs level.

References

There are several publications for GaP decomposition source and valved GaP compound source. Please have a look at section References / List of Publications .

Comparison with other Elemental Phosphorus Cells

Valved Elemental Phosphorus Cracker

Valved GaP Compound Source (VGCS)

principle

- complicated 2-reservoir system

- convertion of red P to white P

- separate high temperature cracker for P 2 forming

- overpressure in reservoir possible and boost problem

- single reservoir GaP sublimation

- natural P 2 source

- no high temperature cracking needed

- efficient Ga trapping

- no pressure boost due to recombination of excess P back to GaP in the reservoir

flux control

- mechanical valve control

- instanteous shut off

- mechanical valve control

- instanteous shut off

source material

- red P chunk, 6N-7N purity

- crystalline GaP chunk, 6N-7N purity

handling + safety

- elemental phosphorus

- reload delicate with lots of white P everywhere

- very high risk of fire

- stable semiconductor crystals

- easy to clean and handle

- no white P in the reservoir

- reloading easy with much lower risk of fire

Technical data

| Filament type | 2 separate heater-circuits (cell / valve) |

| Thermocouple | W5%Re/W26%Re (type C); 2 thermocouples (cell/valve) |

| Operating temperature | cell crucible: 800-950°C; valve: 350°C |

| Outgassing temperature | cell crucible: 1300°C; valve: 500°C |

| Bakeout temperature | 250°C |

| Cooling | integrated water cooling shrouds |

| Crucibles | 420 cm³ |

| Flux control | integrated valve unit |

| Valve control | servo motor drive with control unit MVCU |

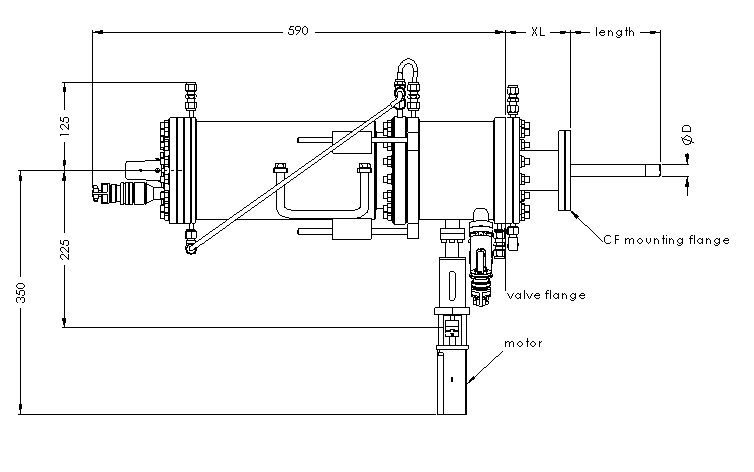

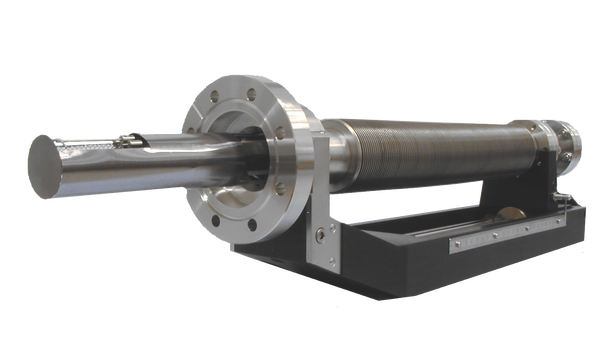

Dimensions

Specific data

For general information on CF mounting flanges see Flange and Gasketdimensions .

| Product | CF flange | Nominal capacity | UHV dimensions*** [mm] | max. electrical [W]/[A] | Power supply product code | |

|---|---|---|---|---|---|---|

| [cm3 ] | [mm] / [mm] | [W] / [A] | Product code | |||

| VGCS | 100*- | 420**- | LxxD57 | cell: 600 / 12 injector: 150 / 7 | cell: PS 70-22-C injector: PS 30-10-C |

* other mounting flange diameters feasible in combination with VADP adapter flanges (on request) ** other capacities on request *** specify UHV length L with order

Product code: e.g. VGCS 100-420-L300D57 is a valved GaP compound souce on DN100 CF flange with 420cm³ crucible and UHV-length 300mm.