- Reservoir Volume 9600 cm³, larger volume on request

- Pneumatically actuated normally closed valve

- Easy refill

- Optimized for fast maintenance

- Robust heater design

- Water-cooled assembly

- Option for carrier gas version

Introduction

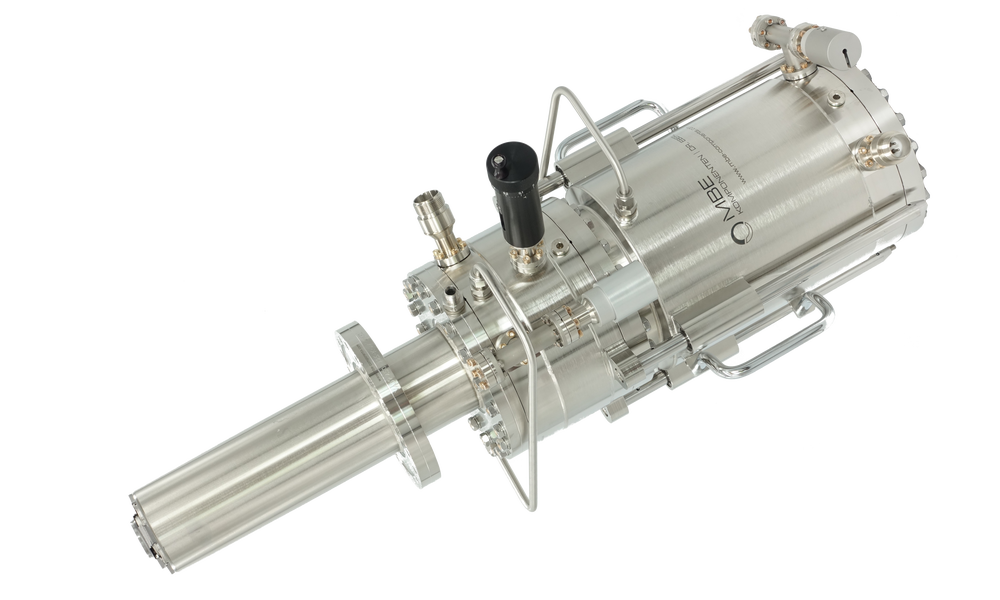

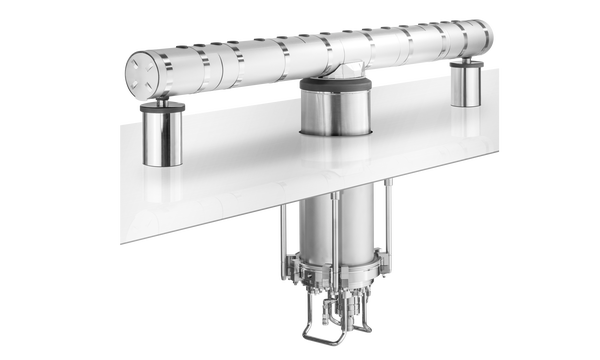

The PVSS is a valved selenium / sulfur source, which is employed in high efficiency CIGS and CIS solar cell production.

Se or S vapor pressure is generated in a heated large capacity glass

crucible. The heaters are positioned in the isolation vacuum surrounding

the crucible, valve and tubes. The outlet of the valve opens into a

customized injector. The isolation vacuum of the source is separated

from the process chamber. The outer walls of the reservoir are water

cooled.

The valve arrangement is robust and eliminates the risk of locking,

which is a frequently observed problem with needle valves.

We offer customized heated gas distribution systems on request.

For more details on the smaller R&D type valved sources see VSCS .

Application

The large versions of the PVSS( valved S / Se Source) can be applied in controlled evaporation of Se / S for the following applications:

- large scale II-VI semiconductor device fabrication

- thin film CIGS or CIS solar cell manufacturing

- sulfurization and selenization processes (including post-growth annealing under process gas) with or without carrier gas

MBE-Komponenten provides support in the design of research or production systems in order to achieve a customized source geometry, optimized for a specified layer uniformity and highly efficient deposition material usage.

| Model | PVSS 320-9600 |

| Operation temperature | max. 350°C |

| Valve | Pneumatic, normally closed |

| crucible volume | 9600 cm³ |

| Glass liner option | 1000 cm³/usable half-sphere |

| Crucible heater | 1550 W |

| Top heater | 1320 W |

| Valve and tube heater | 820 W |

| Power supply | 400 V, 16 A; 50 Hz; 3 Phases |

| Compressed air | 8 - 10 bar |

| Isolation vacuum | < 3 mbar |

| Cooling water pressure | 2,5 bar |

| Water flow rate | 2,2 l/min |