- Compatible with standard High Vacuum systems

- Equipped with O-Ring seal

- Metal Deposition/ Thin Film

- Crucible capacities 40-1700 cm³

- Precise run-to-run flux reproducibility

- Excellent reliability and long lifetime

- Hot lip, cold lip and dual filament designs

- Optional integrated cooling shroud

Introduction

Production Cells PEZ-K are designed to meet the requirements of production High Vacuum systems with higher throughput.

Their wide operating temperature range of 200-1400°C allows evaporation or sublimation of a large number of elements and compounds, such as Cu, Au, Ag, In, Al, Te, or Zn.

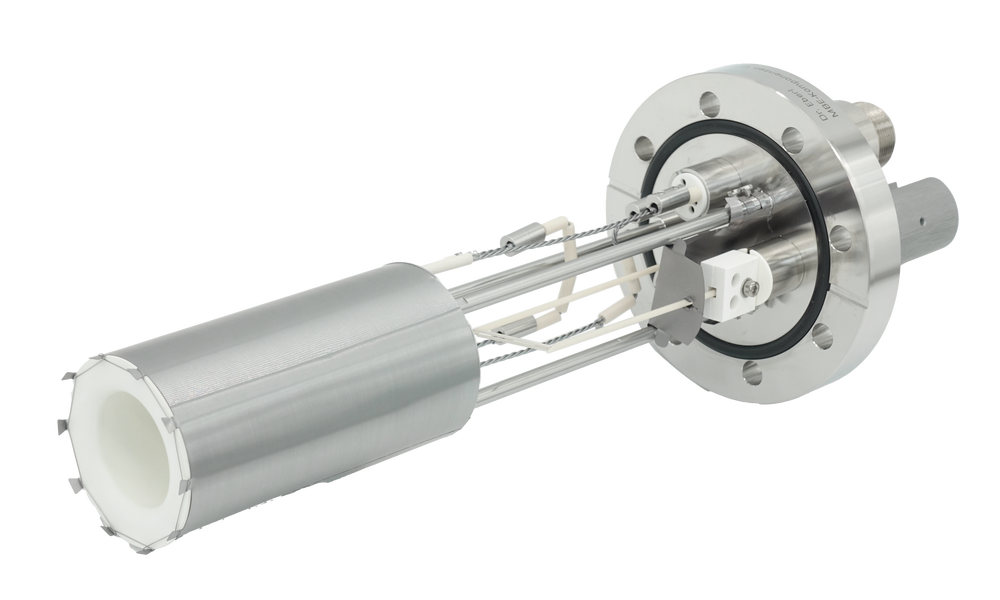

Besides standard filaments SF, hot-lip HL, cold lip CL and dual filament DF configurations are available, meeting the differing requirements of the evaporation materials. The picture on the right-hand side details a PEZ-K with dual filament.

The standard crucible material for the PEZ-K is PBN. PEZ-K cells are either equipped with conical or cylindrical crucibles, depending on the HV chamber design, and offer precise flux reproducibility and excellent thickness uniformity.

Further improvements of source material utilization and flux stability can be achieved by using a customized beam shaping insert in combination with a large capacity crucible. Crucible inserts not only reduce the effect of fill level-related flux shift but also act as a thermal buffer virtually eliminating shutter transients for more details).

Similar to our standard evaporation cells, the crucible is heated by a wire filament supported by PBN rings. The advantages of this heating assembly are described on page. The consequent use of power and TC feedthroughs on separate DN16 CF flanges allows easy servicing.

For large scale production systems crucible capacities up to 1700 cm³ (and more) are available.

Application

The PEZ-K is recommended for elements and compounds evaporated or sublimated at temperatures in the range 200-1400°C, e.g. Cu, Au, Ag, In, Al, Te, or Zn etc. The PEZ-K is distinguished by a more robust cell design and the consequent optimization of many details leading to a further improvement of stability and reproducibility, as well as excellent reliability and easy servicing.

For HV applications that require a wide-area homogeneous growth, the use of conical crucibles is recommended. A compact hot lip filament improves the critical power management in the upper crucible zone by reducing the heater wire temperature, equivalent to less chemical corrosion. In addition, the more robust radiation shielding and cell heater housing as well as flange protection tubes reduce the risk of chemical corrosion and electrical short-circuits caused by liquid metals (gallium).

Crucibles

Standard crucible material for the PEZ-K is PBN. Other crucible materials are available upon request. Depending on evaporation material and chamber geometry, PEZ-K cells can be equipped either with conical (e.g. 40 cm³, 60 cm³, 1700 cm³) or cylindrical crucibles. Unless explicitly refused, PEZ-K cells with cylindrical crucible are delivered as standard with an additional customized beam shaping crucible insert.