In the field of Molecular Beam Epitaxy (MBE), standard products may not always meet the unique requirements of every deposition system or experimental setup. At our company, we recognize the diverse needs of researchers and engineers working with MBE technology. We are committed to providing customized solutions that address specific challenges faced by our clients. As demonstrated through various examples, our expertise extends to creating:

- Compact sources for tight spaces

- Multi-source clusters on limited flange sizes

- Specialized configurations for existing systems

- Adaptations for unique geometries and orientations

Please do not hesitate to contact us in case our standard MBE products do not fit into your deposition system or are incompatible with the special geometry of your experiment. We will work closely with you in order to find a solution for your specific issue.

Typical examples of customized solutions are:

- You may need a very small evaporation source to fit into a tight surface science apparatus. We offer very compact sources on small flanges.

- You may need a very compact source cluster to evaporate two different materials alternately or simultaneously. The source should be equipped with water cooling and with shutters. The available mounting flange is only DN40CF.

- You may need even 4 small sources on a single DN100CF flange and fully equipped with shutters and cooling shroud.

- You may need two sources on one regular source flange on your Riber system or your GEN II MBE. For example, you want to incorporate two doping sources (Be and Si) into one source port.

- A DN100CF flange with with 90° orientation to the sample (previously used, for example, for an e-beam evaporator) shall be converted into a mounting flange for thermal evaporation sources.

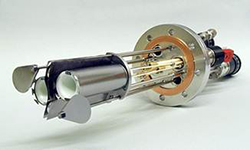

- High purity Si needs to be deposited in a GEN II MBE system. The

drawing on the right side shows a vertical e-beam evaporator fitted

into the growth chamber.

The crucible is tilted in order to enable Si evaporation onto the vertically oriented substrate. It allows to melt the Si and thereby to achieve high deposition rates in this flat angle source flange geometry.

Conclusion:

These customized solutions showcase our ability to innovate and adapt our technology to meet precise specifications. Whether it’s miniaturizing components, integrating multiple sources, or developing entirely new configurations, we strive to overcome the limitations of standard MBE products. We encourage researchers and engineers facing compatibility issues or special requirements to reach out to us. Our team is dedicated to collaborating closely with clients to develop tailored solutions that enable cutting-edge research and development in the field of MBE. By combining our technical expertise with a customer-centric approach, we aim to push the boundaries of what’s possible in molecular beam epitaxy and support the advancement of scientific discovery and technological innovation.

Our team has many years of active research experience and long experience in manufacturing of MBE components. We are happy to discuss your system specifications and give competent advice for your application. Please contact us if you need a very special solution for your MBE growth project.