- Compatible with all MBE systems

- Crucible capacity 300 cm³, 500 cm³ or 2000 cm³

- Large valve opening

- Precise and very fast flux control

- Easy handling and refilling procedure

- Integrated water cooling shrouds Datasheet

Introduction

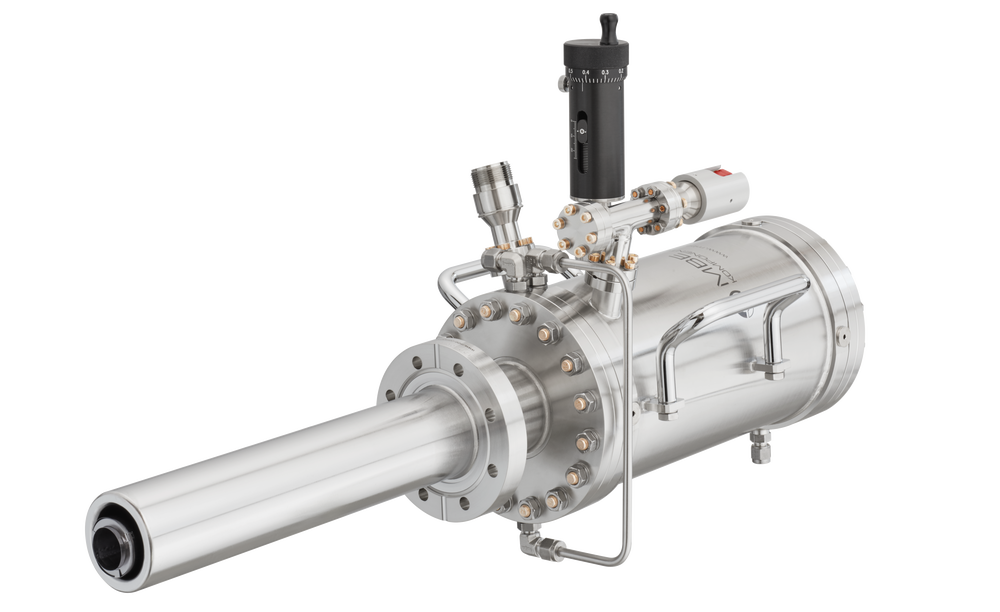

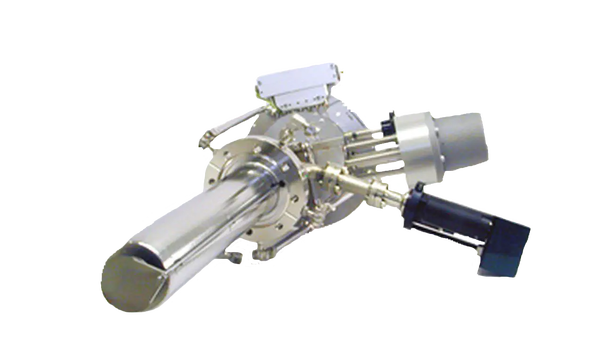

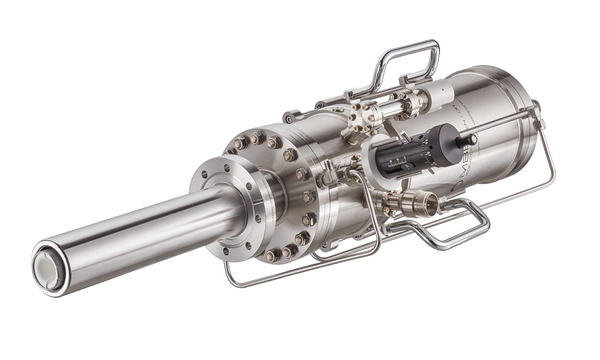

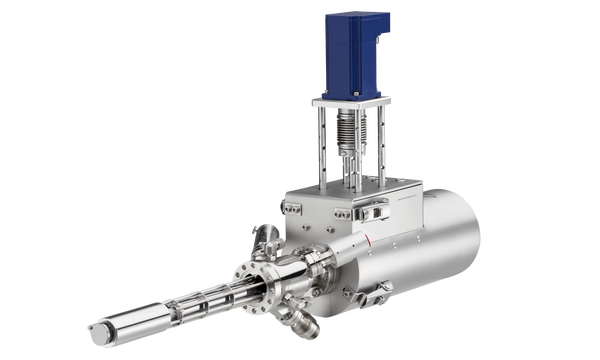

The Valved Arsenic Cracker Source VACS is designed for high performance growth of III-V materials.

The VACS is highly specialized for As 4 or As 2 sublimation and combines large crucible capacity of 300 cm³, 500 cm³ or for industrial applications even 2000 cm³ with precise and fast flux control. A flux control range of more than two orders of magnitude is provided by the integrated valve mechanism. The typical on/off ratio is about four orders of magnitude.

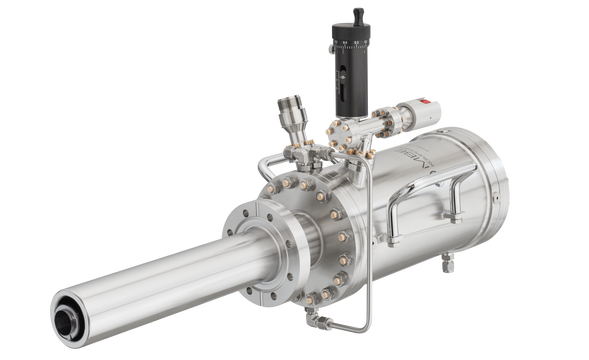

The valve unit can be operated manually or with an additional valve control unit (MVCU) which controls the valve position by an external

analogue voltage (0…10V), see picture on the right.

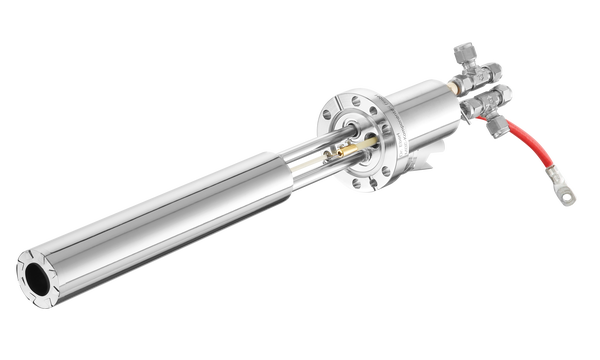

The integrated water cooling shroud and the use of selected materials

for cell and valve unit guarantee high purity operation conditions. The

operation mode of the source can be easily changed from As

4 to As 2

growth by the operation conditions of the integrated

cracker unit.

The special design allows an easy refilling of the crucible from the backside without removing the cell from the chamber. It is also not necessary to completely empty the reservoir before refilling it. For refilling it is recommended to prepare a few cylindrical blocks with 1/3 or 1/4 height of the reservoir. This simplifies your maintenance work and saves your time.

The typical valve characteristic, i.e. the beam equivalent pressure (BEP) as a function of the valve position, is shown on the right. The graph indicates the wide flux range of more than two orders of magnitude which is smoothly controlled on a wide value position range of several millimetres, when operated with a MVCU. The MVCU has a spatial resolution of 1/100 mm. This smooth operation condition guarantees a precise and reproducible flux control for your application. Together with a high motor speed of 10 mm/s a fast control is reached.

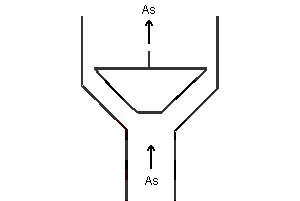

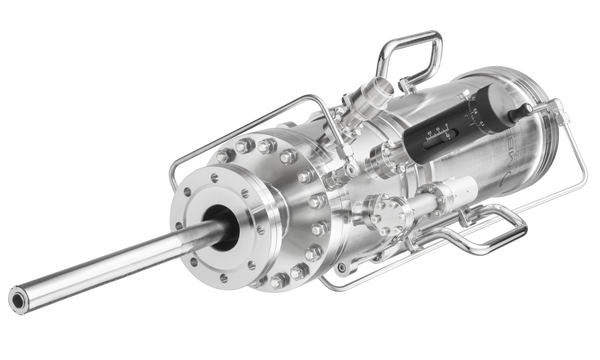

The design of the valve mechanism is schematically illustrated on the right side. It provides a large cross section opening which allows very good pumping of the As reservoir. The robust wide angle valve design effectively elimitates the chance of locking, which is a frequently observed problem for needle valves.

The VACS has proven to be a very reliable As source in the field. It is compatible to commonly used industrial and research MBE systems.

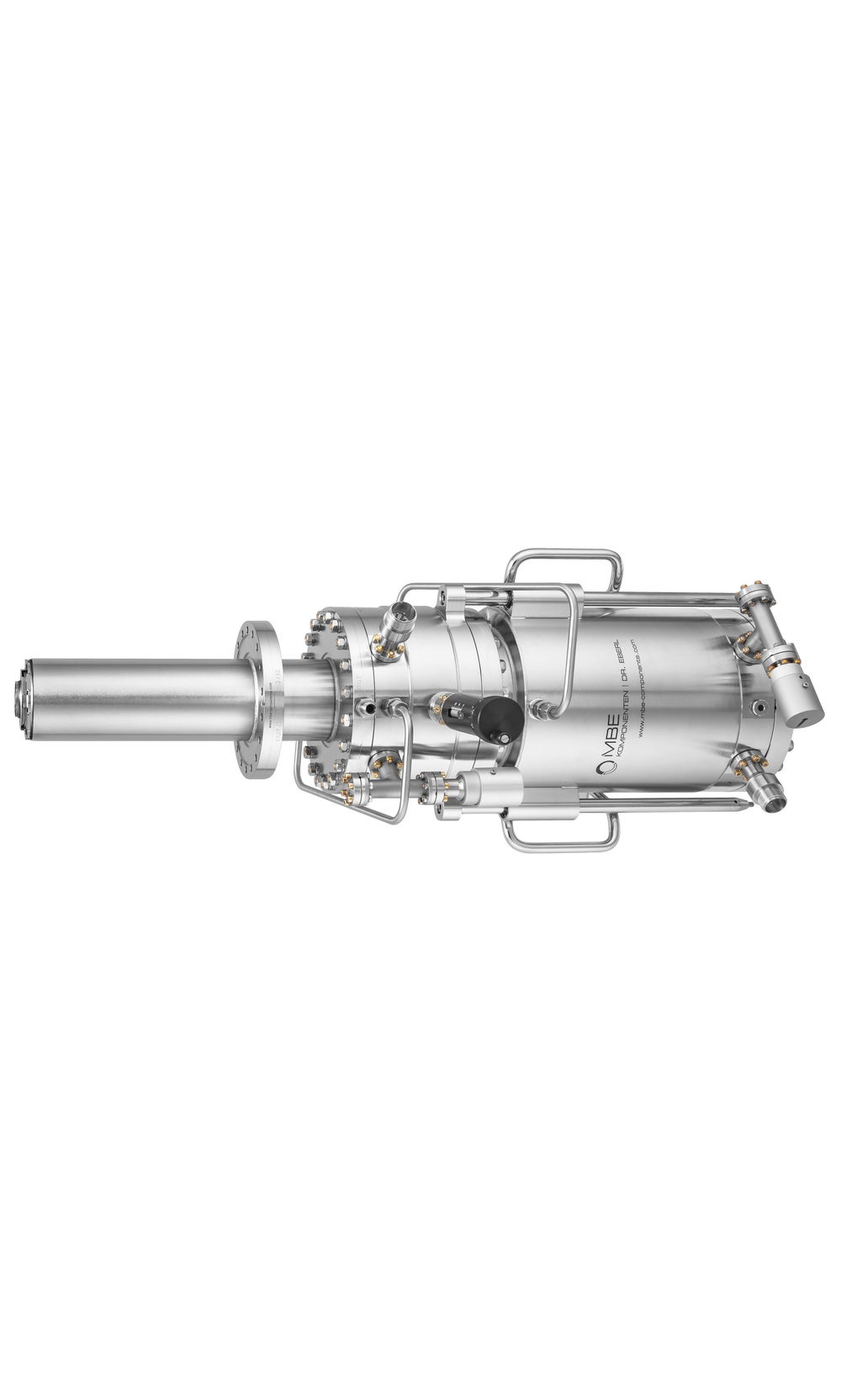

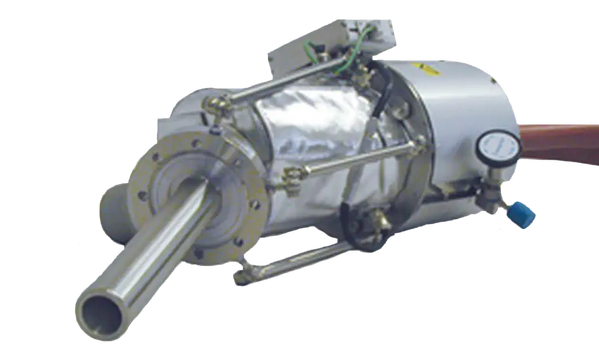

The large version VACS 150-2000 with 2000 cm3 crucible capacity (see picture on the right) is especially designed for industrial applications. It is particularly suitable for MBE systems such as OCTOPLUS 600 and OCTOPLUS 800.

Application

The VACS is used for As 4 or As

2 sublimation in III-V MBE.

Large crucible capacity (300 cm³, 500 cm³ or 2000 cm³), fast and precise

flux control and easy handling for maintenance and crucible refill make

the VACS ideal for smaller production MBE systems as well as for higher

throughput research MBE systems.

BEP vs. time, with valve on and off (cell temp. 390°C / cracker temp. 600°C).

The motorized valve control allows to adjust and switch the As 2 flux within seconds within about 3 orders of magnitude

SIMS of GaInP on GaAs buffer layer on (100) GaAs substrate with VACS and VGCS applied Very sharp transitions of As are achieved by application of VACS and VGCS sources at one deposition run. 300 nm GaInP are deposited on a GaAs buffer layer on a (100) GaAs substrate. Due to the fast flux control properties of the valve unit the As concentration in the GaInP layer is at its detection limit, i.e. three orders of magnitude below the GaAs level, which is demonstrated by the top right SIMS measurement. In return, P is sharply reduced on the GaInP/GaAs interface.

Technical data

| VACS 100-300 / VACS 100-500 | VACS 150-2000 | |

| Filament type | 2 separate heater-circuits (reservoir/cracker) | 3 separate heater-circuits (reservoir/valve/cracker) |

| Thermocouple | W5%Re/W26%Re (type C); 2 thermocouples (cell/cracker) | W5%Re/W26%Re (type C); 3 thermocouples (cell/cracker) |

| Operating temperature | reservoir: 300-450°C; cracker: 500°C (As 4 -mode) - 1100°C (As 2 -mode) | reservoir: 300-450°C valve: 320-470°C cracker: 500°C (As4 -mode) - 1100°C (As2 -mode) |

| Outgassing temperature | reservoir: 500°C; cracker: 1200°C | reservoir: 480°C valve: 500°C cracker: 1200°C |

| Bakeout temperature | 250°C | 250°C |

| Cooling | integrated water cooling shrouds | integrated water cooling shrouds |

| Crucible | 300 cm³ or 500 cm³ | 2000 cm³ |

| Flux control | integrated valve unit | integrated valve unit |

| Valve control | hand control, or motor drive with control unit MVCU | hand control, or motor drive with control unit MVCU |

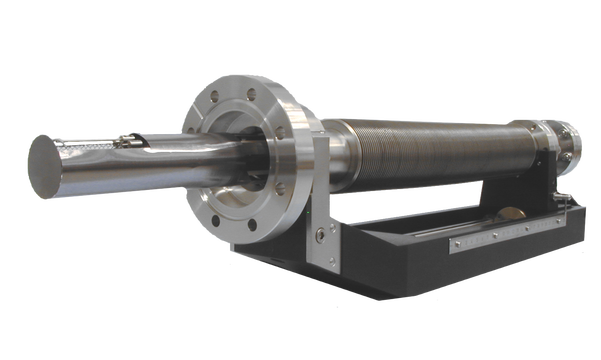

| In-vacuum dimensions | L=360 mm - AL D, SL = customer specific ID=33 mm / 38 mm | L=360 mm - AL D, SL = customer specific ID=38 mm |

| Airside dimensions | AL= customer specific OL=290 mm / 375 mm AR= 208 mm | AL= customer specific OL=566 mm AR= 260 mm |

| Weight | 22 kg | 45.5 kg |

Dimensions

Specific data

For general information on CF mounting flanges see Flange and Gasketdimensions .

| Product | CF flange | Nominal capacity | UHV dimensions*** [mm] | max. electrical [W]/[A] | Power supply product code | |

|---|---|---|---|---|---|---|

| [cm3 ] | [mm] / [mm] | [W] / [A] | Product code | |||

| VACS | 100* - | 300**- | LxxxD57 | cell: 200 / 6 cracker: 300/ 10 | 2x PS 70-10-C | |

| VACS | 100*- | 500**- | LxxxD57 | cell: 300 / 6 injector: 300 / 10 | 2x PS 70-10-C | |

| VACS | 150*- | 2000**- | LxxxD89 | reservoir: 300 / 6 valve: 200 / 6 cracker: 300 / 10 | 3x PS 70-10-C |

* other mounting flange diameters feasible in combination with VADP adapter flanges (on request) ** other capacities on request *** specify UHV length L with order

Product code: e.g. VACS 100-300-L290D57 is a valved arsenic cracker source on DN100 CF flange with 300cm³ crucible capacity and UHV-length 290mm.